↓↓下拉很多 ➟➟微信☎

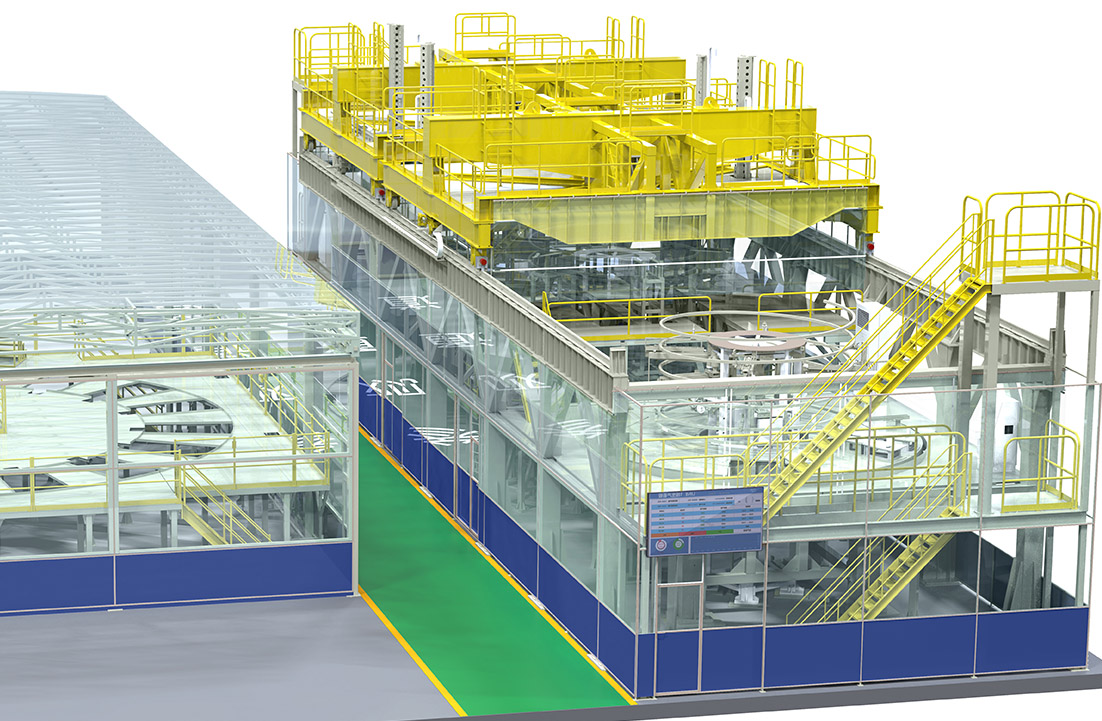

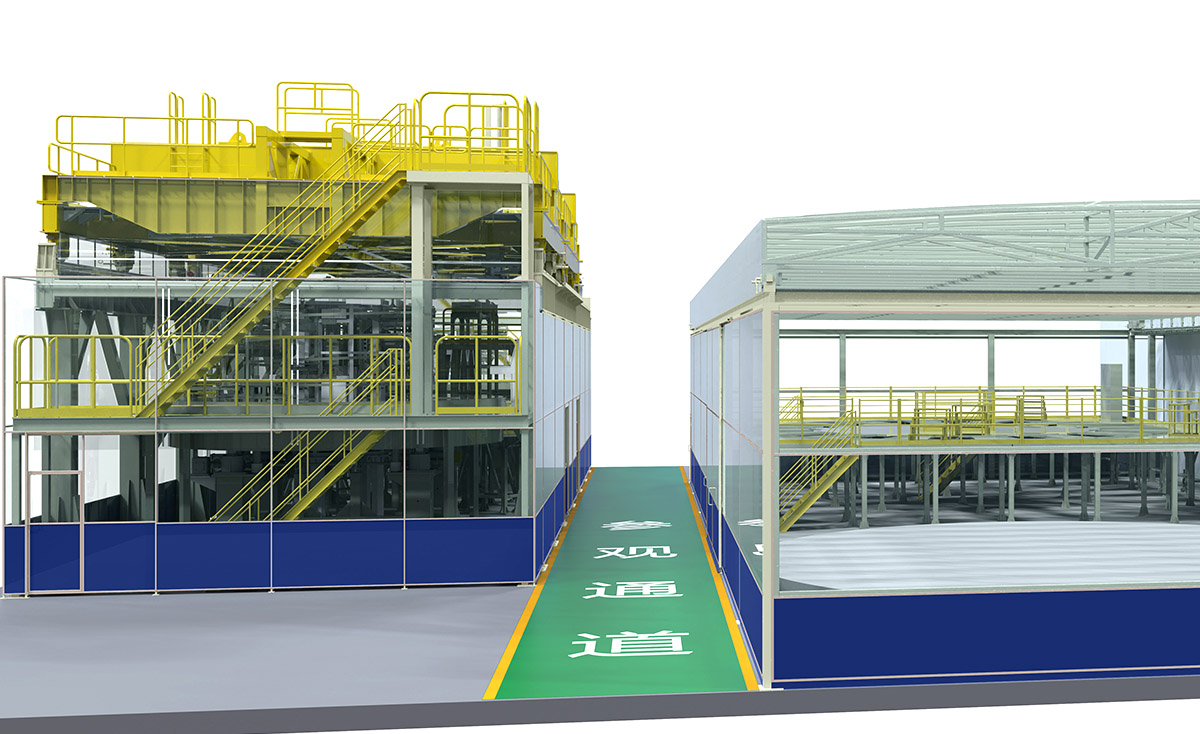

研磨生产线动画渲染制作:

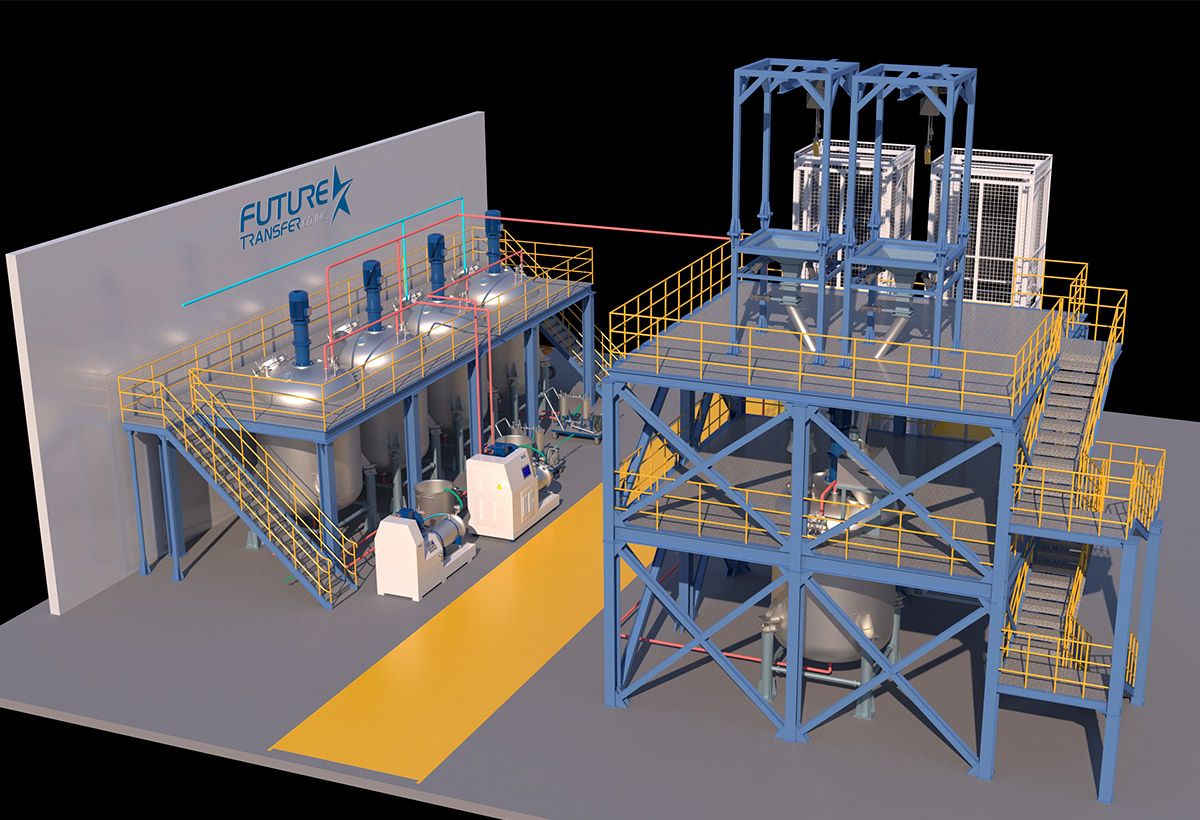

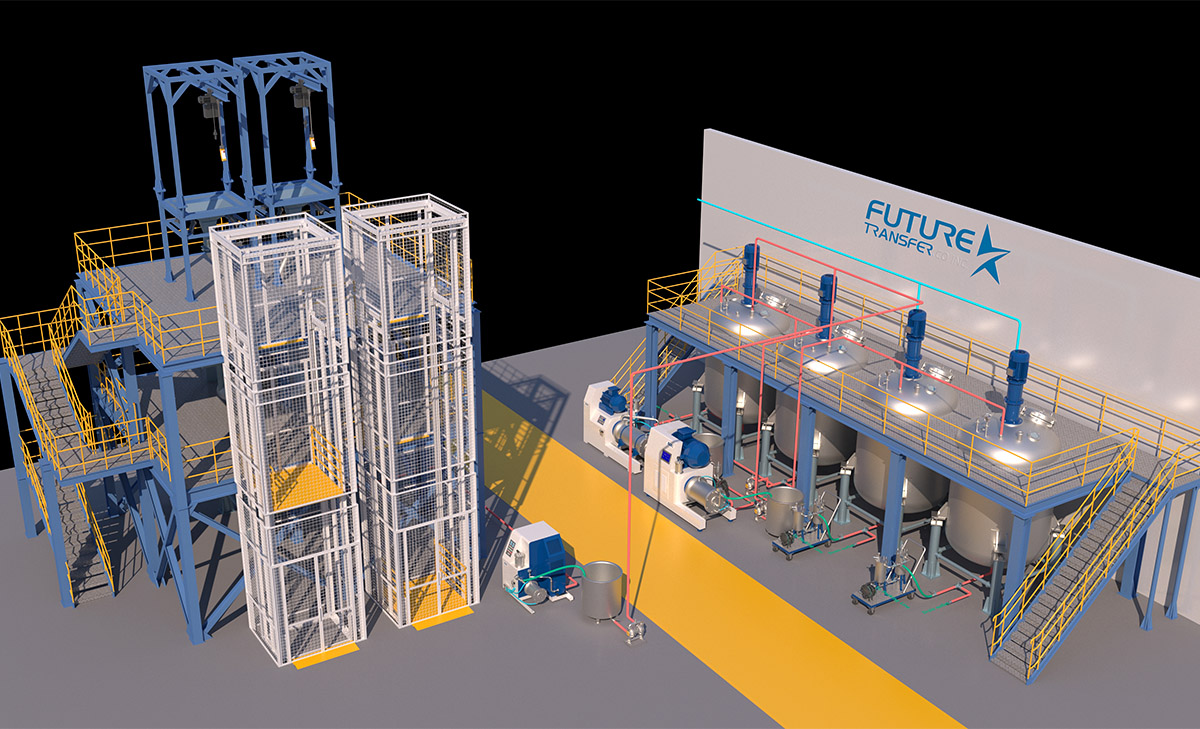

固液分离搅拌动画渲染制作:

抛丸加工生产线动画渲染制作:

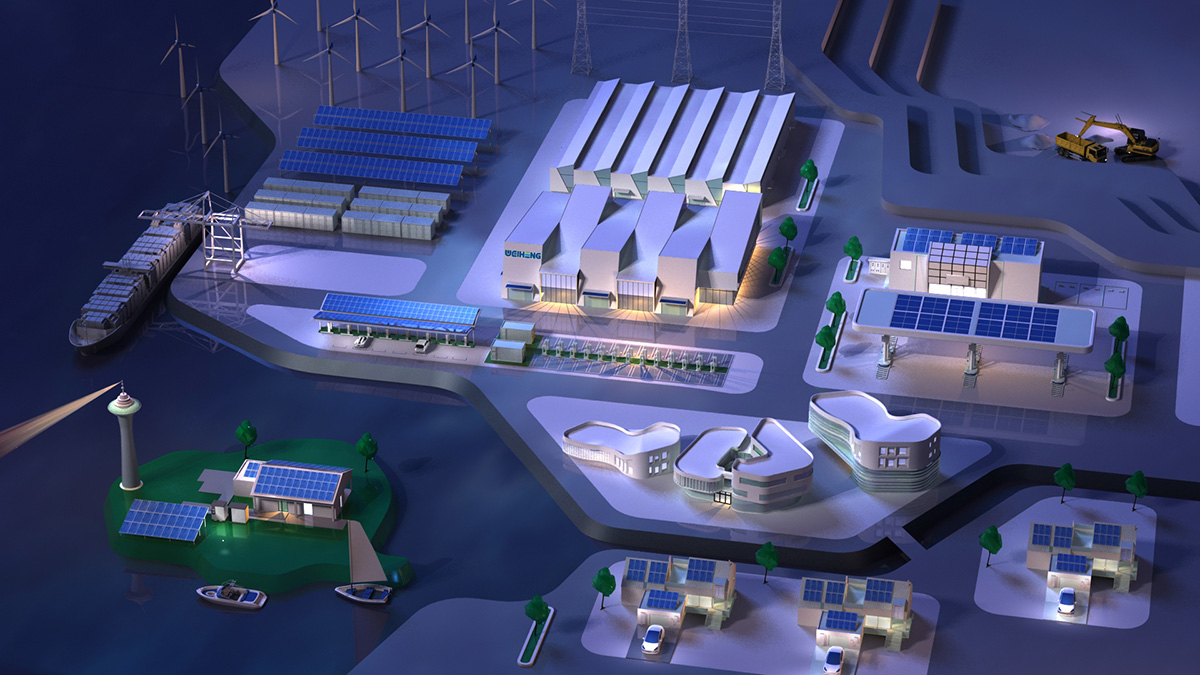

金盘科技的户外储能柜动画渲染制作:

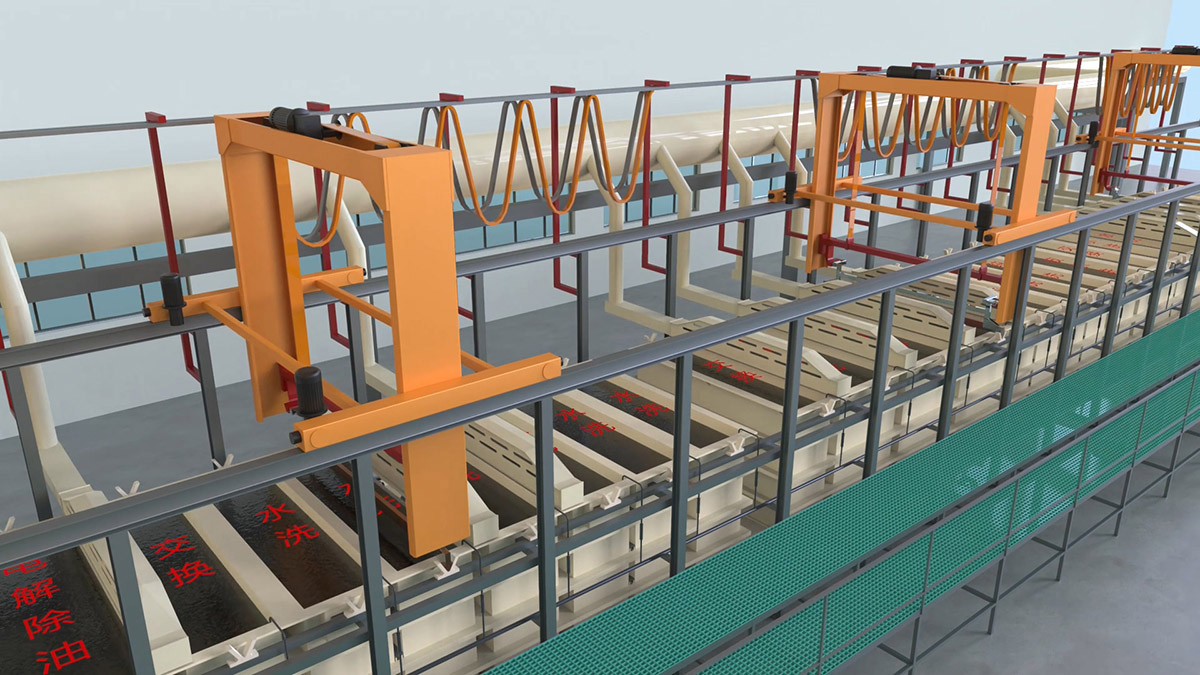

太阳能板生产加工展示动画渲染制作:

加工机床设备的三维动画渲染制作:

生产车间流水线动画渲染制作:

大型仓库物流生产线动画渲染制作:

生猪加工流水线动画渲染制作:

智能仓储工作流程动画渲染制作:

木材加工生产线动画渲染制作:

车间自动化处理一体流水线动画渲染制作:

自动化生产线的3D动画渲染制作:

包装生产线的3D动画渲染制作:

******** 点击 返回主页_看更多案例 ********

其它三维渲染图:

******** 点击 返回主页_看更多案例 ********

流水线动画对企业有多方面的影响,主要包括提升品牌形象、增强客户信任、降低销售成本、优化生产流程、提高培训效果和促进技术交流与合作等。

首先,流水线动画能够直观地展示企业的生产流程和技术水平,帮助客户更好地理解产品的制造过程和质量标准,从而提升企业的品牌形象和客户信任度。通过三维动画的形式,企业可以将复杂的生产线流程以直观、立体的方式呈现,增强客户的沉浸式体验,使客户仿佛身临其境地感受生产线的每一个细节。

其次,流水线动画在营销和推广方面具有显著优势。它能够吸引客户的注意力,展示企业的生产能力和技术水平,从而提高企业的竞争力。此外,通过动画展示生产线的高效运作,可以增强客户对产品质量的信心,促进销售成交。

在内部管理和培训方面,流水线动画可以作为高效的培训工具,帮助新员工快速熟悉企业的各种流程,提高培训效果和效率,降低培训成本。同时,员工能够更好地遵循标准化流程工作,减少错误和重复劳动,提升整体工作效率。

此外,流水线动画在优化生产流程和促进技术交流与合作方面也有重要作用。通过动画仿真,企业可以预先发现潜在的问题和风险,优化生产线的布局和流程,减少不必要的等待时间和资源浪费,提高生产效率。同时,动画仿真能够促进与合作伙伴之间的技术交流与合作,展示生产线的技术特点和优势。

研磨生产线动画在多个方面具有显著影响:

提高生产效率:通过研磨生产线动画,企业可以直观地了解生产线的运行流程和各个环节之间的关联,从而发现潜在的生产瓶颈,优化生产流程,提高生产效率。

降低生产成本:动画可以帮助企业分析生产过程中的浪费和不必要成本,通过展示合理的设备布局和物料搬运方式,减少不必要的人力和物力投入,从而降低生产成本。

提高产品质量:动画可以展示生产过程中关键参数和可能出现的问题,企业可以及时进行调整和改进,从而提高产品质量。

培训员工:研磨生产线动画可以作为企业培训的重要教材,帮助新员工快速熟悉生产过程,提高员工的技能水平。此外,动画还可以作为企业内部培训资料,让员工在空闲时间自主学习,提高整体素质。

市场推广:研磨生产线动画可以向客户展示企业的技术水平和生产能力,增加客户对企业的信任度,从而增加合作机会。

技术交流与合作:动画可以作为技术交流的工具,帮助企业与其他企业或研究机构分享技术成果和经验,吸引更多的合作机会和投资。

抛丸加工生产线动画对企业形象有显著的提升作用。通过高质量的三维动画,企业可以直观地展示生产线的运行过程和技术优势,从而增强客户和合作伙伴的信任和认可。

首先,抛丸加工生产线动画能够生动展示生产线的运作流程和技术特点。通过三维动画,企业可以详细展示生产线的每一个环节,包括抛丸机的操作、清理效果等,使观众能够直观地理解生产线的效率和效果。这种直观的展示方式比文字或图片介绍更加吸引人,有助于提升企业在行业内的知名度和品牌形象。

其次,抛丸加工生产线动画有助于企业建立专业、可靠的形象。通过高度真实和直观的动画展示,潜在客户和投资者能够一目了然地了解企业的生产流程和技术实力,从而对企业产生信任和好感。这种信任和好感进一步转化为企业的市场竞争力,帮助企业在激烈的市场竞争中脱颖而出。

此外,抛丸加工生产线动画还可以帮助企业发现潜在的问题和瓶颈,并通过动画模拟进行提前改进和优化。这种前瞻性的问题解决方式不仅提升了生产线的运行效率,还展示了企业的创新能力和技术实力,进一步增强了企业的品牌形象。

我们是专业3d渲染制作,产品渲染图制作,工业模型渲染,模型渲染,设备渲染图制作公司,擅长企业医疗器械、助行器、电力设备、产品、机械设备、化工工艺、安装、组装、工业机电设备、水利设备、石化设备、电力工程建设、电梯、施工、机械、钢构、投标、建筑规划设计、工业园区厂房、环保、光伏发电等领域,提供专业的3d渲染设计服务,并拥有大量3D动画制作+3d产品模型外观渲染图制作经验。

物流生产线3D动画主要包括以下几种类型:

滚筒输送机3D动画:适用于各种物品的输送,具有结构简单、维护方便、噪音低等特点。滚筒输送机可以根据需要定制,满足不同的输送需求。

皮带输送机3D动画:广泛应用于物流、食品、电子等行业,具有输送量大、结构简单、维护方便等优点。皮带输送机可以根据需要定制,包括直角拐弯运输机、环形物流生产流水线等。

链板输送线3D动画:分为重型和轻型两种,重型链板线适用于汽车、家电等行业,轻型链板线适用于食品、电子等行业。链板输送线具有输送效率高、能耗低、故障率低等特点。

生猪加工流水线动画中要展示的主要功能包括接收、检疫、屠宰、分割、包装和质检等环节。具体来说:

接收区:负责接收、检验并暂存生猪,确保进入生产线的生猪符合卫生与安全要求。

检疫区:对生猪进行检疫,确保其健康无疫情。

屠宰区:通过电击晕、刺杀放血、剥皮等工序完成屠宰,确保屠宰过程高效且安全。

分割区:利用先进的分割机械和清洗设备,将猪肉分割成不同部位,并进行肉质评估和分级。

包装区:对分割后的猪肉进行分拣、包装并标记,以便后续的运输和销售。

质检区:对包装完成的肉类进行最终质量检验,确保产品符合质量标准,并记录生产数据以利于追溯与管理。

此外,生猪加工流水线还具备以下特点:

高效性:通过自动化设备和工艺处理步骤,实现了从原料到成品的高效转化,显著提高了生产效率。

安全性:采用先进的屠宰技术和设备,确保生猪在无痛苦、无恐惧的状态下被迅速屠宰,避免了因过度挣扎而产生的肉质损伤和淤血。

卫生性:严格遵守国家卫生标准和食品安全法规,对生产环境、设备、工具等进行严格的清洁和消毒,确保猪肉在加工、储存和运输过程中始终保持新鲜、卫生。

环保性:采用先进的废水处理技术和废弃物回收技术,减少环境污染和生态破坏,提高资源利用效率。

智能仓储动画视频中体现出来的是一个集自动化、信息化和物流化于一体的仓储管理系统,通过采用先进的技术手段和设备,极大地提高了仓库的货物存储效率和管理精度。智能仓储系统3D动画主要包括以下组成部分:

立体货架:用于存储货物,提供高效的存储空间利用。

有轨巷道堆垛机:用于自动搬运和堆垛货物,提高物流效率。

出入库输送系统:实现货物的自动进出库操作。

信息识别系统:通过RFID、条形码等技术对货物进行准确识别。

自动控制系统:确保设备的自动化运行和协调作业。

计算机监控系统:实时监控仓库的运作情况,提高管理效率。

计算机管理系统:记录和管理仓库的各项数据,支持决策分析。

辅助设备:如手持RFID设备、智能拣选系统等,辅助日常操作和管理。

此外,智能仓储还利用物联网技术,通过先进的控制、总线、通讯等手段,实现对各类设备的自动出入库作业。这些技术手段包括人工智能、大数据、云计算等,进一步提升了仓储管理的智能化水平。

木材加工生产线动画视频中体现出来的主要包括以下几种:

全自动原木木材加工生产线3D动画:这种生产线用于处理原木,将其加工成各种规格的木材产品。它通常包括原木切割、锯切、刨光等工序。

细木工板生产线3D动画:利用小径木、枝桠材、木材加工剩余物等木质原料,经过拌胶后压制成刨花板。这种生产线适用于处理各种木质废料,将其再利用制成板材。

实木家具生产线3D动画:这种生产线用于生产实木家具,包括备料、切割、打磨、组装等工序。拥有先进的实木加工技术,生产红橡、白橡、水曲柳、榆木等优质木材制成的家具。

木工板生产线设备3D动画:包括木料清洗皮带线、数控开料机、打孔机、封边机等设备,用于生产各种规格的木工板和家具部件。这些设备通常用于板式家具和实木家具的生产。

不同类型木材加工生产线的应用场景和所需设备3D动画如下:

全自动原木木材加工生产线3D动画:需要原木切割机、刨光机、传送带等设备。

细木工板生产线3D动画:需要拌胶机、压机、切割机等设备。

实木家具生产线3D动画:需要备料设备、切割工具、打磨设备、组装设备等。

木工板生产线设备3D动画:包括清洗皮带线、数控开料机、打孔机、封边机等。

这些生产线和设备3D动画的应用场景广泛,适用于家具制造、建筑材料生产等多个领域,能够高效地处理和加工各种木质材料,满足不同行业的需求。

包装生产线3D动画可以分为以下几类:

3D动画按自动化程度分类:

自动包装流水线3D动画:通过自动化设备和机械手臂等装置,实现产品的自动取放、计量、填充、封口、贴标等包装过程。适用于大批量、高效率的包装需求,能显著提高生产效率和降低人工成本。

半自动包装流水线3D动画:需要人工参与部分包装环节,如放置产品、调整包装材料等。适用于中小批量生产,灵活性较高。

手动包装流水线3D动画:依赖人工完成整个包装过程,适用于小批量生产或特殊产品的包装,能满足个性化、定制化的需求。

3D动画按包装材料分类:

纸质包装流水线3D动画:使用纸张、纸板等环保材料,适用于食品、药品等需要防潮、防尘、防污染的产品包装。

塑料包装流水线3D动画:使用塑料薄膜、塑料袋等材料,适用于电子产品、五金制品等需要防潮、防尘、防摔的产品包装。

玻璃包装流水线3D动画:使用玻璃瓶、玻璃罐等材料,适用于酒类、化妆品等需要展示产品质感和美观度的产品包装。

3D动画按包装工艺分类:

热封包装流水线3D动画:通过加热使包装材料熔化并粘合,适用于塑料袋、塑料膜等热塑性材料的包装。

冷封包装流水线3D动画:使用特殊的冷封胶对包装材料进行粘合,适用于对热敏感的产品包装,如药品、食品等。

贴标包装流水线3D动画:在包装过程中自动将标签贴在产品上,适用于需要标识产品信息、生产日期、批次号等的产品包装。

按应用领域分类:

食品包装流水线:专门用于食品类产品的包装,需要满足食品安全、卫生等要求。

医药包装流水线:用于药品的包装,需要满足防潮、防尘、防污染等特殊要求。

我们是专业的3d渲染制作公司-工业产品设备3d模型,产品外观渲染图制作,专业制作三维渲染图的动画公司,为企业、政府机构、科教院校、设计院、工程建设安装施工、房地产、新能源环保行业、电器数码产品工业、智能家居、装饰公司、汽车智能系统、石油化工业、医疗器械设备、机械产品制造业、生产线企业、铁路采掘业、纺织业、船舶航空领域,提供一站式方案设计,打造企事业形象、提高品牌竞争力。

Production line animation has multiple impacts on enterprises, including enhancing brand image, strengthening customer trust, reducing sales costs, optimizing production processes, improving training effectiveness, and promoting technical exchange and cooperation.

Firstly, assembly line animation can visually display a company's production process and technological level, helping customers better understand the manufacturing process and quality standards of products, thereby enhancing the company's brand image and customer trust. Through the form of 3D animation, enterprises can present complex production line processes in an intuitive and three-dimensional way, enhancing customers' immersive experience and making them feel as if they are immersed in every detail of the production line.

Secondly, assembly line animation has significant advantages in marketing and promotion. It can attract customers' attention, showcase the production capacity and technological level of the enterprise, thereby enhancing its competitiveness. In addition, showcasing the efficient operation of the production line through animation can enhance customers' confidence in product quality and promote sales transactions.

In terms of internal management and training, assembly line animation can serve as an efficient training tool to help new employees quickly familiarize themselves with various processes of the enterprise, improve training effectiveness and efficiency, and reduce training costs. At the same time, employees can better follow standardized processes, reduce errors and repetitive labor, and improve overall work efficiency.

In addition, assembly line animation also plays an important role in optimizing production processes and promoting technical exchange and cooperation. Through animation simulation, enterprises can identify potential problems and risks in advance, optimize the layout and process of production lines, reduce unnecessary waiting time and resource waste, and improve production efficiency. At the same time, animation simulation can promote technical exchange and cooperation with partners, showcasing the technical characteristics and advantages of the production line.

The animation of the grinding production line has significant impacts in multiple aspects:

Improving production efficiency: By grinding production line animations, companies can intuitively understand the operation process of the production line and the relationships between each link, thereby discovering potential production bottlenecks, optimizing production processes, and improving production efficiency.

Reduce production costs: Animation can help companies analyze waste and unnecessary costs in the production process, reduce unnecessary manpower and material investment by demonstrating reasonable equipment layout and material handling methods, and thus lower production costs.

Improving product quality: Animation can showcase key parameters and potential issues in the production process, allowing companies to make timely adjustments and improvements to enhance product quality.

Training employees: Grinding production line animations can serve as important teaching materials for enterprise training, helping new employees quickly familiarize themselves with the production process and improve their skill levels. In addition, animation can also serve as internal training materials for enterprises, allowing employees to learn independently in their free time and improve their overall quality.

Market promotion: Grinding production line animation can showcase the technical level and production capacity of the enterprise to customers, increase their trust in the enterprise, and thus increase cooperation opportunities.

Technical exchange and cooperation: Animation can serve as a tool for technical exchange, helping companies share technological achievements and experiences with other enterprises or research institutions, attracting more opportunities for cooperation and investment.

The animation of shot blasting production line has a significant impact on enhancing the corporate image. Through high-quality 3D animation, enterprises can visually display the operation process and technological advantages of their production lines, thereby enhancing the trust and recognition of customers and partners.

Firstly, the animation of shot blasting production line can vividly demonstrate the operation process and technical characteristics of the production line. Through 3D animation, companies can showcase every step of the production line in detail, including the operation of shot blasting machines, cleaning effects, etc., allowing the audience to intuitively understand the efficiency and effectiveness of the production line. This intuitive display method is more attractive than text or image introductions, and helps to enhance the company's visibility and brand image in the industry.

Secondly, animation of shot blasting production lines helps enterprises establish a professional and reliable image. Through highly realistic and intuitive animation displays, potential customers and investors can have a clear understanding of the company's production processes and technological capabilities, thereby generating trust and goodwill towards the company. This trust and goodwill further translate into the market competitiveness of the enterprise, helping it stand out in the fierce market competition.

In addition, animation of shot blasting production lines can help companies identify potential problems and bottlenecks, and make early improvements and optimizations through animation simulation. This forward-looking problem-solving approach not only improves the operational efficiency of the production line, but also demonstrates the company's innovation capability and technological strength, further enhancing the brand image of the enterprise.

We are a professional company specializing in 3D rendering production, product rendering, industrial model rendering, model rendering, and equipment rendering. We specialize in enterprise medical equipment, walkers, power equipment, products, mechanical equipment, chemical processes, installation, assembly, industrial electromechanical equipment, water conservancy equipment, petrochemical equipment, power engineering construction, elevators, construction, machinery, steel structure, bidding, architectural planning and design, industrial park buildings, environmental protection, photovoltaic power generation, and other fields. We provide professional 3D rendering design services and have extensive experience in 3D animation production and 3D product model appearance rendering.

The 3D animation of logistics production lines mainly includes the following types:

3D animation of drum conveyor: suitable for conveying various items, with the characteristics of simple structure, easy maintenance, and low noise. Roller conveyors can be customized according to needs to meet different conveying requirements.

Belt conveyor 3D animation: widely used in logistics, food, electronics and other industries, with advantages such as large conveying capacity, simple structure, and easy maintenance. Belt conveyors can be customized according to needs, including right angle turning conveyors, circular logistics production lines, etc.

3D animation of chain plate conveyor line: divided into two types: heavy and light. Heavy chain plate line is suitable for industries such as automobiles and home appliances, while light chain plate line is suitable for industries such as food and electronics. Chain plate conveyor line has the characteristics of high conveying efficiency, low energy consumption, and low failure rate.

The main functions to be displayed in the animation of pig processing pipeline include receiving, quarantine, slaughtering, segmentation, packaging, quality inspection and other links. Specifically:

Reception area: responsible for receiving, inspecting, and temporarily storing live pigs to ensure that the pigs entering the production line meet hygiene and safety requirements.

Quarantine area: Quarantine pigs to ensure their health and absence of epidemics.

Slaughtering area: Slaughtering is completed through processes such as electrocution, bloodletting, and skinning to ensure efficient and safe slaughter.

Segmentation zone: Utilizing advanced segmentation machinery and cleaning equipment, pork is segmented into different parts and subjected to meat quality evaluation and grading.

Packaging area: Sort, package, and label the segmented pork for subsequent transportation and sales.

Quality inspection area: Conduct final quality inspection on packaged meat to ensure that the product meets quality standards, and record production data for traceability and management.

In addition, the pig processing assembly line also has the following characteristics:

Efficiency: Through automated equipment and process steps, efficient conversion from raw materials to finished products has been achieved, significantly improving production efficiency.

Safety: Advanced slaughter techniques and equipment are used to ensure that pigs are slaughtered quickly without pain or fear, avoiding meat damage and bruising caused by excessive struggle.

Hygiene: Strictly comply with national hygiene standards and food safety regulations, clean and disinfect the production environment, equipment, tools, etc. to ensure that pork remains fresh and hygienic during processing, storage, and transportation.

Environmental friendliness: Adopting advanced wastewater treatment and waste recycling technologies to reduce environmental pollution and ecological damage, and improve resource utilization efficiency.

The intelligent warehousing animation video reflects a warehousing management system that integrates automation, informatization, and logistics. By adopting advanced technology and equipment, it greatly improves the storage efficiency and management accuracy of goods in the warehouse. The 3D animation of the intelligent warehousing system mainly includes the following components:

Stereoscopic shelves: used for storing goods and providing efficient utilization of storage space.

Rail tunnel stacker crane: used for automatic handling and stacking of goods, improving logistics efficiency.

Inbound and outbound transportation system: realizing automatic inbound and outbound operations of goods.

Information recognition system: Accurately identify goods through technologies such as RFID and barcodes.

Automatic control system: Ensure the automated operation and coordinated operation of equipment.

Computer monitoring system: Real time monitoring of warehouse operations to improve management efficiency.

Computer management system: records and manages various data of the warehouse, supports decision analysis.

Auxiliary equipment: such as handheld RFID devices, intelligent picking systems, etc., to assist in daily operations and management.

In addition, intelligent warehousing also utilizes IoT technology to achieve automatic inbound and outbound operations of various devices through advanced control, bus, communication and other means. These technological means include artificial intelligence, big data, cloud computing, etc., further enhancing the intelligence level of warehouse management.

The animation videos of the wood processing production line mainly include the following:

3D animation of fully automatic raw wood processing production line: This production line is used to process raw wood into various specifications of wood products. It usually includes processes such as cutting logs, sawing, planing, etc.

3D animation of particleboard production line: Using small diameter wood, branch wood, wood processing residues and other wooden materials, after mixing glue, they are pressed into particleboard. This production line is suitable for processing various types of wood waste and reusing it into boards.

3D animation of solid wood furniture production line: This production line is used for producing solid wood furniture, including material preparation, cutting, polishing, assembly and other processes. We have advanced solid wood processing technology to produce furniture made of high-quality wood such as red oak, white oak, water chestnut, elm, etc.

3D animation of woodworking board production line equipment: including wood cleaning belt line, CNC cutting machine, punching machine, edge banding machine and other equipment, used for producing various specifications of woodworking boards and furniture components. These devices are typically used for the production of panel furniture and solid wood furniture.

The application scenarios and required equipment 3D animations for different types of wood processing production lines are as follows:

3D animation of fully automatic wood processing production line: requires equipment such as wood cutting machine, planer, conveyor belt, etc.

3D animation of particleboard production line: requires equipment such as glue mixer, press, cutting machine, etc.

Solid wood furniture production line 3D animation: requires material preparation equipment, cutting tools, polishing equipment, assembly equipment, etc.

3D animation of woodworking board production line equipment: including cleaning belt lines, CNC cutting machines, punching machines, edge banding machines, etc.

These production lines and equipment have a wide range of application scenarios for 3D animation, suitable for multiple fields such as furniture manufacturing and building material production. They can efficiently process and process various wooden materials to meet the needs of different industries.

The 3D animation of packaging production lines can be divided into the following categories:

3D animation is classified by degree of automation:

3D animation of automatic packaging assembly line: Through automated equipment and mechanical arms, the packaging process of automatic picking, placing, measuring, filling, sealing, labeling, etc. of products is realized. Suitable for large-scale and high-efficiency packaging needs, it can significantly improve production efficiency and reduce labor costs.

Semi automatic packaging assembly line 3D animation: requires manual participation in some packaging processes, such as placing products, adjusting packaging materials, etc. Suitable for small and medium-sized production, with high flexibility.

Manual packaging assembly line 3D animation: relying on manual completion of the entire packaging process, suitable for small batch production or packaging of special products, and can meet personalized and customized needs.

3D animations classified by packaging materials:

3D animation of paper packaging assembly line: using environmentally friendly materials such as paper and cardboard, suitable for packaging products such as food and medicine that require moisture, dust, and pollution prevention.

3D animation of plastic packaging assembly line: using materials such as plastic film and plastic bags, suitable for packaging electronic products, hardware products, and other products that require moisture, dust, and drop resistance.

3D animation of glass packaging assembly line: using materials such as glass bottles and jars, suitable for packaging products such as alcoholic beverages and cosmetics that need to showcase their texture and aesthetic appeal.

3D animation classified by packaging technology:

3D animation of heat sealed packaging assembly line: melting and bonding packaging materials through heating, suitable for packaging thermoplastic materials such as plastic bags and plastic films.

Cold sealed packaging assembly line 3D animation: using special cold sealing glue to bond packaging materials, suitable for packaging products that are sensitive to heat, such as drugs, food, etc.

3D animation of labeling and packaging assembly line: Automatically attaching labels to products during the packaging process, suitable for packaging products that require identification of product information, production date, batch number, etc.

Classified by application field:

Food packaging assembly line: specifically designed for packaging food products that meet requirements for food safety, hygiene, and other aspects.

Pharmaceutical packaging assembly line: used for packaging drugs, it needs to meet special requirements such as moisture resistance, dust prevention, and pollution prevention.

We are a professional 3D rendering production company specializing in the production of industrial product equipment 3D models, product appearance rendering, and animation. We provide one-stop solution design for enterprises, government agencies, science and education institutions, design institutes, engineering construction and installation, real estate, new energy and environmental protection industries, electrical and digital product industries, smart homes, decoration companies, automotive intelligent systems, petrochemical industry, medical equipment, mechanical product manufacturing, production line enterprises, railway mining industry, textile industry, shipbuilding and aviation fields, creating corporate image and enhancing brand competitiveness.

QQ咨询

QQ咨询

189 5158 0154

189 5158 0154

在线留言

在线留言