***** 最新作品_右侧微信联系 *****

↓↓下拉很多 ➟➟微信☎

车间模型全景360旋转渲染制作:

医疗设备模型全景旋转展示渲染制作:

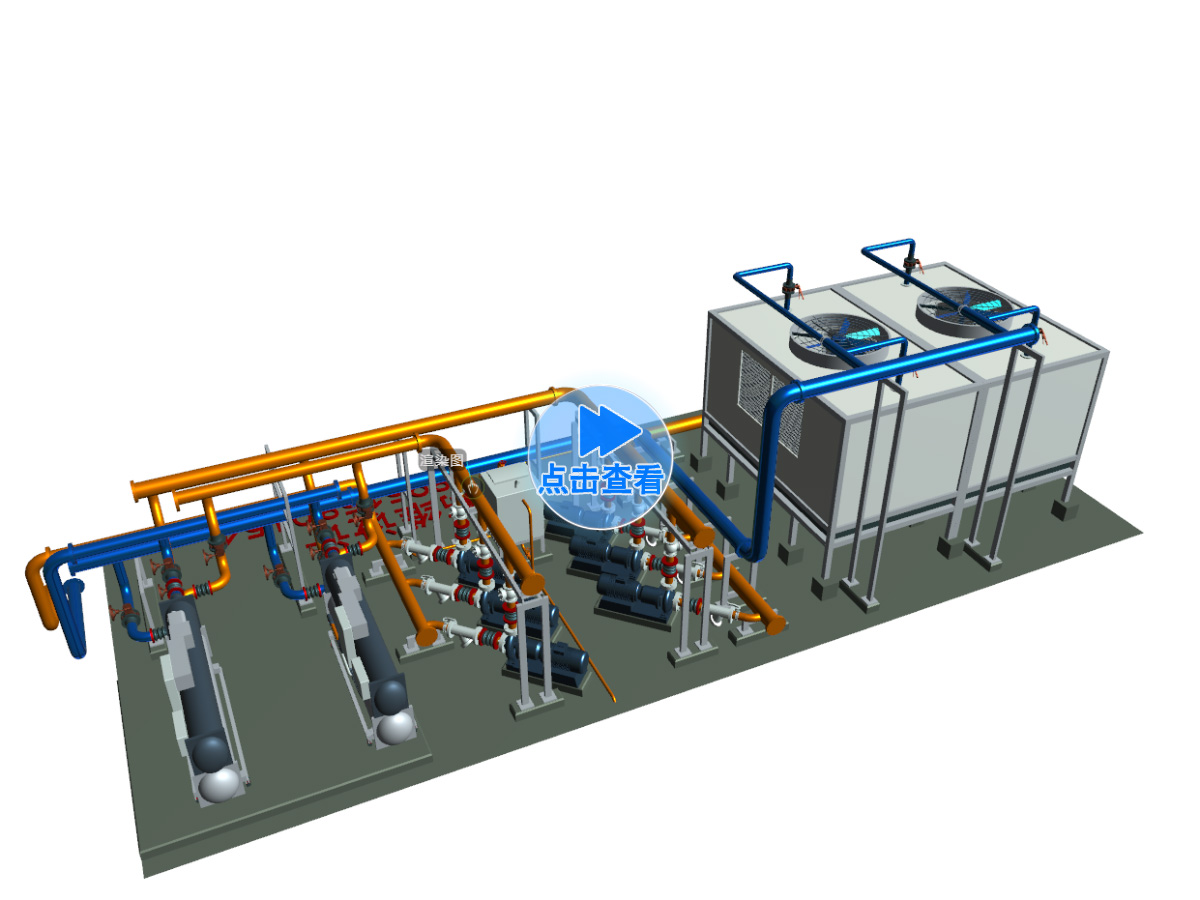

拌合站模型全景360旋转渲染制作:

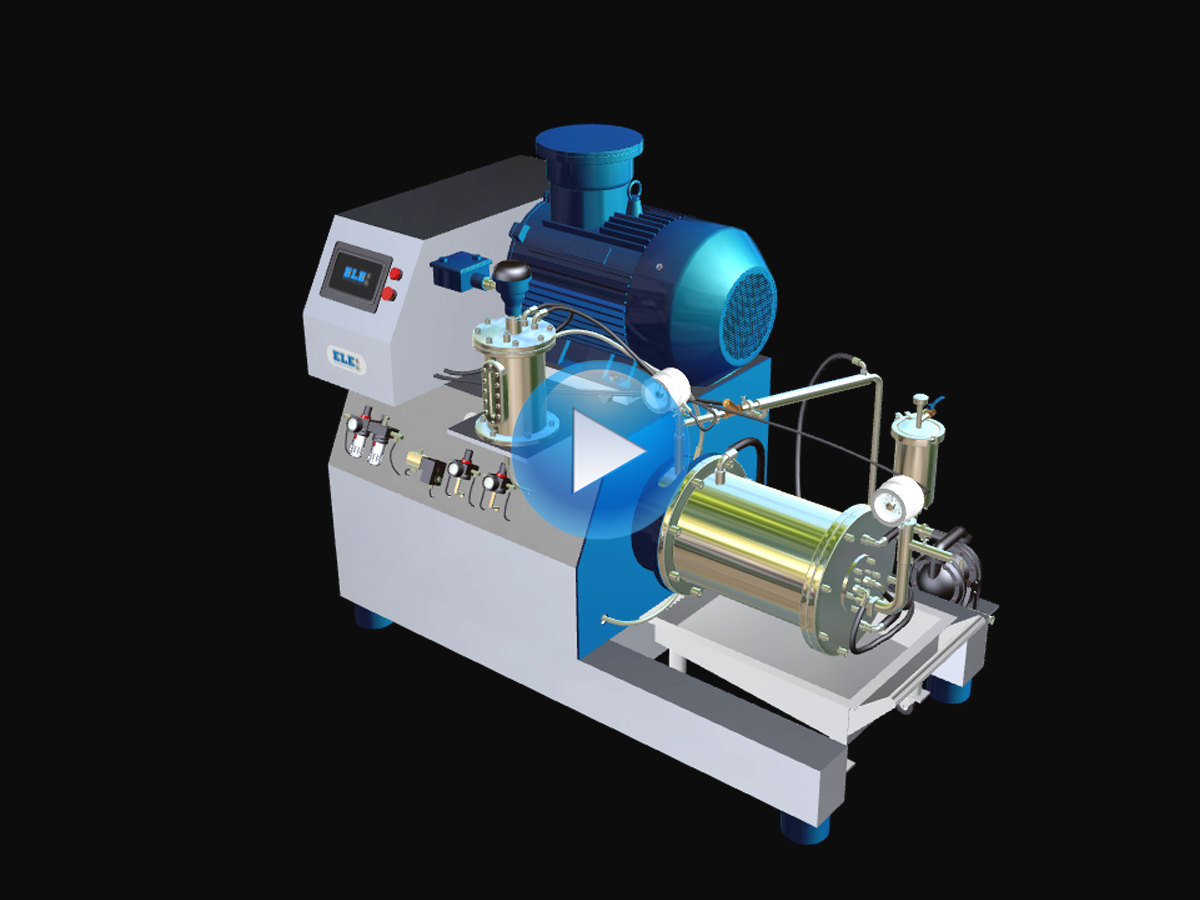

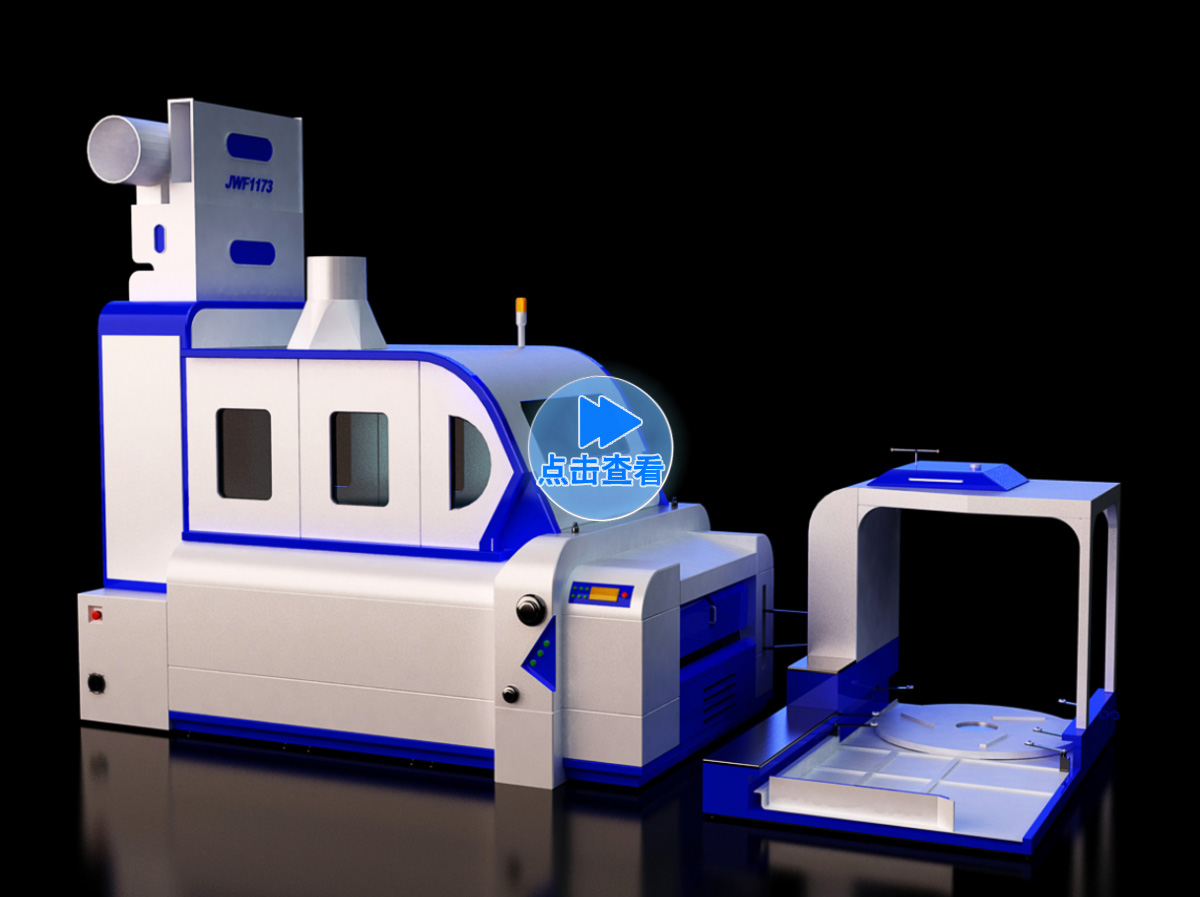

工业模型全景旋转渲染制作:

机械臂模型全景360旋转渲染制作:

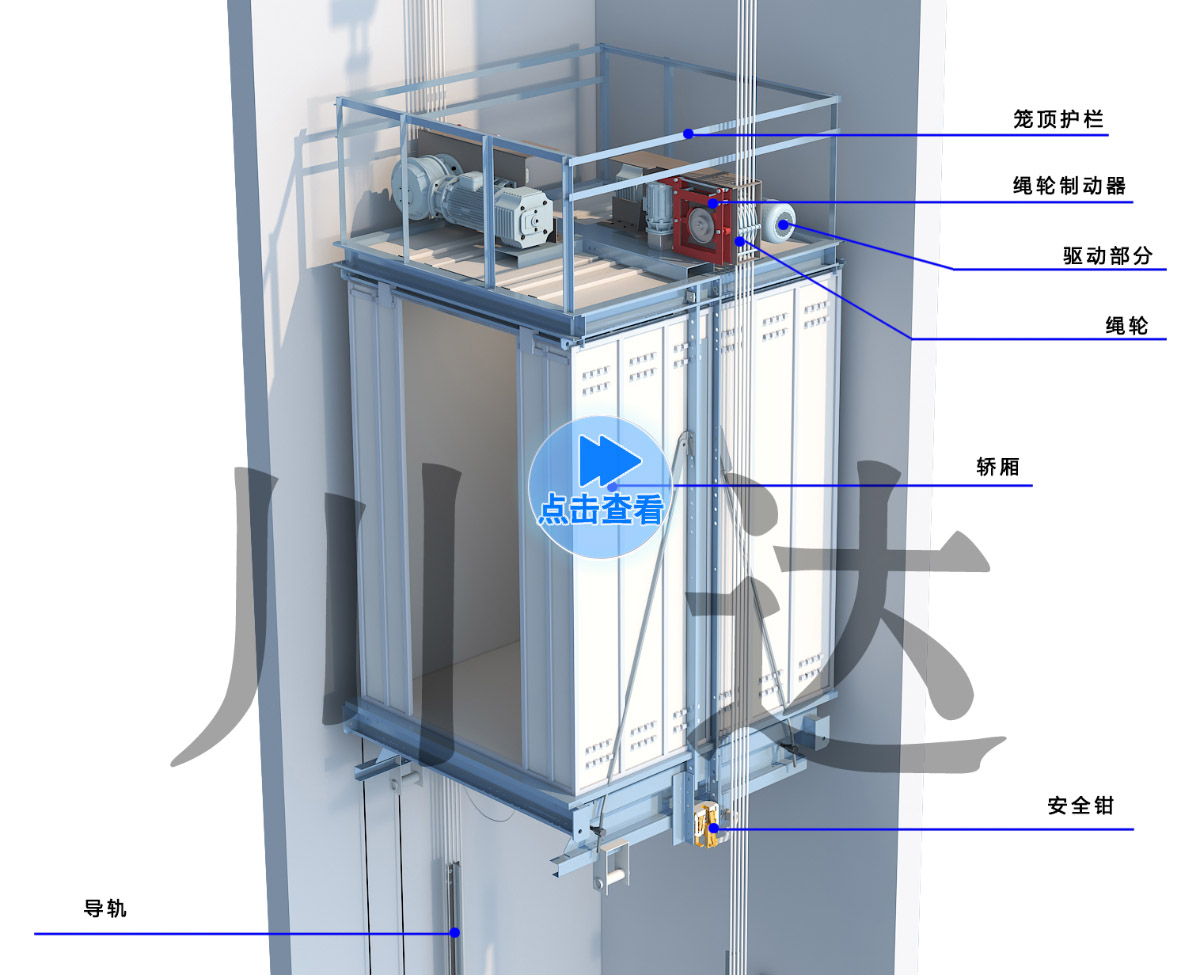

爬升式电梯模型全景360旋转渲染制作:

固态火箭动画渲染制作:

设备模型全景360旋转渲染制作:

AR_VR_MR:

管道液体仿真动画特效:

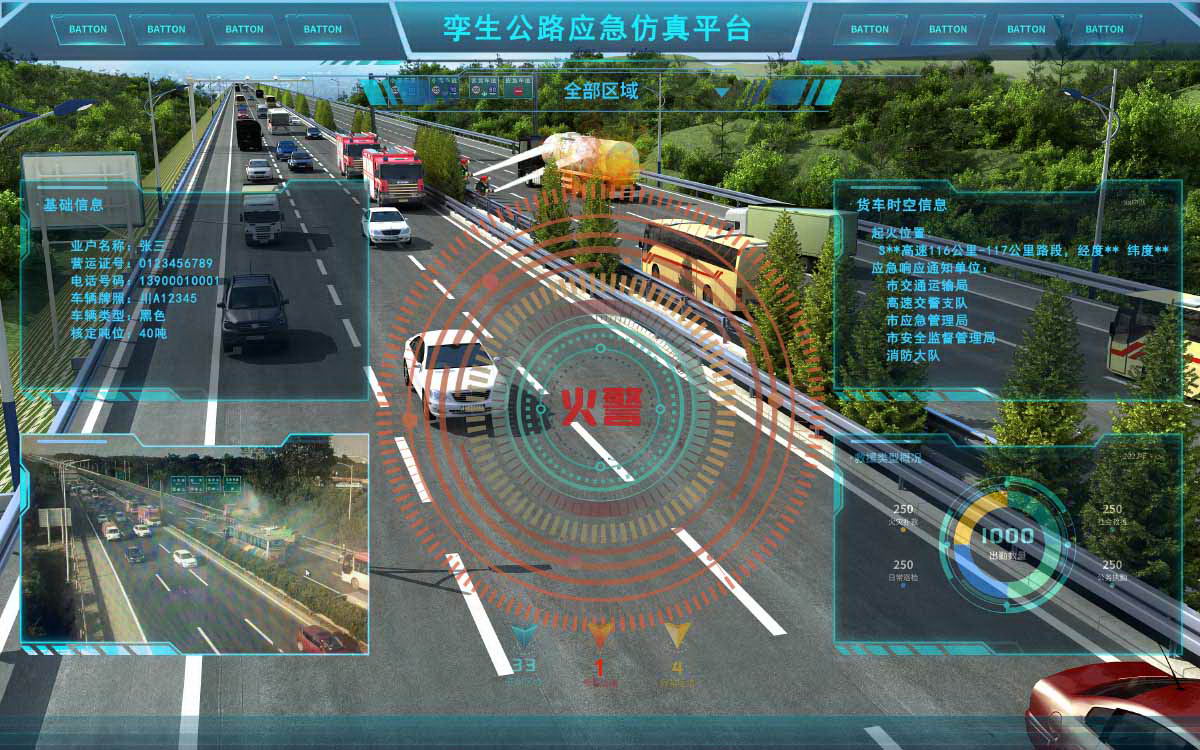

3D仿真交互系统:

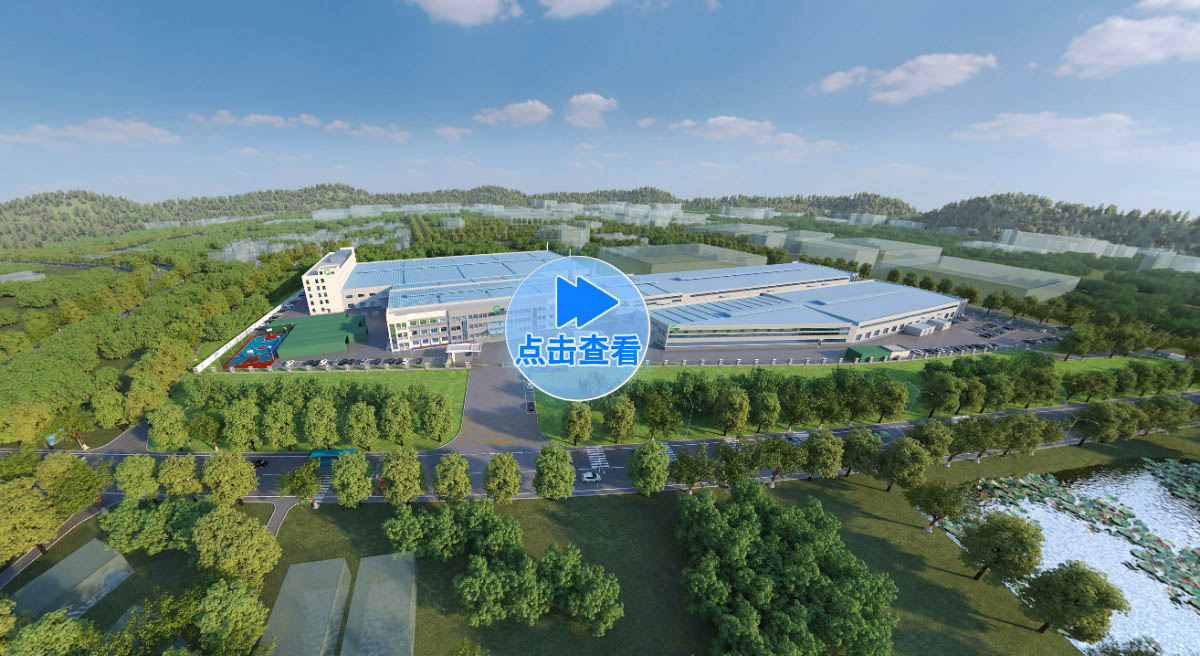

厂区360全景图旋转:

厂房全景图旋转:

******** 点击 返回主页_看更多案例 ********

AR、VR、MR和全景技术是四种不同的技术,它们在交互方式和应用场景上各有特点。

AR(增强现实)(Augmented Reality)技术通过电脑技术将虚拟信息叠加到真实世界中,使用户能够在现实环境中看到虚拟元素。AR的典型应用包括“AR红包”功能,通过手机摄像头扫描现实世界的物体,并在屏幕上显示相关的图片、音视频和3D模型。AR技术的特点是虚实结合,实时交互,能够增强现实世界的视觉效果和互动体验。

VR(虚拟现实)(Virtual Reality)技术通过计算机生成一个完全虚拟的世界,使用户沉浸其中。VR设备如头戴式显示器(HMD)结合跟踪系统,提供实时渲染、真实空间和真实交互的体验。VR的应用非常广泛,包括游戏、影视、专业学习与训练、旅游、制造和军事等领域。VR技术的特点是沉浸性、交互性和构想性,能够模拟真实世界的视觉、听觉和触觉体验。

MR(混合现实)(Mixed Reality)技术是在虚拟环境中引入现实场景信息,实现虚拟世界和现实世界之间的交互反馈。MR的关键在于与现实世界的交互和信息获取,通常需要一个能够与现实世界各事物相互交互的环境。MR的应用包括医生在相隔两地的同步手术操作,以及在5G网络支持下进行的远程交流。

3D全景技术通常指的是360度全景图像或视频,能够提供全方位的视野体验。全景技术常用于虚拟旅游、房地产展示、在线教育等领域,使用户能够身临其境地探索虚拟环境。全景技术与AR和VR技术相结合,可以提供更加沉浸式的体验。

拌合站模型全景360旋转通过360度全景技术,模拟出一个可交互的三维空间场景,使用户能够全方位、多角度地查看拌合站的各个部分和细节。这种技术不仅展示了拌合站的外观和结构,还能让用户通过鼠标或触摸屏控制旋转、缩放等操作,实现沉浸式的体验。

360度全景技术通过使用多个高清摄像头从不同角度拍摄场景,然后将这些图像拼接成一个完整的全景图像。用户可以通过鼠标或触摸屏控制视角的旋转和缩放,实现360度无死角的查看。这种技术在工业设计、房地产展示、旅游景点介绍等领域有广泛应用,能够提供更加直观和生动的展示效果。

在拌合站模型的全景展示中,360度全景技术可以应用于以下几个方面:

外观展示:展示拌合站的外观设计和整体布局,用户可以查看拌合站的各个角度和细节。

内部结构:通过全景技术,用户可以查看拌合站的内部结构,了解各个设备的位置和功能。

操作流程:展示拌合站的操作流程和工艺流程,帮助用户更好地理解其工作原理。

维护保养:提供拌合站的维护保养指南,帮助用户了解如何进行日常维护和故障排查。

通过这些应用,360度全景技术能够为用户提供更加直观、全面的拌合站信息,提升用户体验和效率。

我们是专业3d渲染制作,产品渲染图制作,工业模型渲染,模型渲染,设备渲染图制作公司,擅长企业医疗器械、助行器、电力设备、产品、机械设备、化工工艺、安装、组装、工业机电设备、水利设备、石化设备、电力工程建设、电梯、施工、机械、钢构、投标、建筑规划设计、工业园区厂房、环保、光伏发电等领域,提供专业的3d渲染设计服务,并拥有大量3D动画制作+3d产品模型外观渲染图制作经验。

机械臂模型全景360度旋转是指通过360度旋转机械臂模型,使其在三维空间中自由旋转,从而展示机械臂的各个角度和细节。360度旋转机械臂模型主要用于展示和交互设计。通过全景展示,用户可以直观地看到机械臂的各个部分和细节,方便进行设计和优化。例如,在工业设计中,设计师可以通过360度旋转模型来调整机械臂的结构和功能,确保其在各种工作场景中的表现和安全性。360度旋转机械臂模型通常通过计算机图形技术和虚拟现实(VR)技术实现。通过软件模拟,用户可以在虚拟环境中自由旋转模型,查看不同角度的细节。这种技术不仅提高了设计的效率和准确性,还为用户提供了更加直观和互动的体验。在工业设计中,360度旋转机械臂模型被广泛应用于机器人和自动化设备的设计中。设计师可以通过这种模型详细地展示机械臂的各个部件和运动轨迹,确保其在复杂工作环境中的稳定性和高效性。

3D仿真交互系统是一种将物理世界转换成数字模型,并在虚拟环境中进行模拟和优化的技术。它利用计算机图形学、虚拟现实技术和交互设计等技术,使用户能够与数字模型进行交互和操作。3D仿真交互系统通常包括数字建模、虚拟现实技术和交互式操作等技术手段,通过这些技术手段,用户可以在虚拟环境中对数字模型进行观察、分析和优化。

3D仿真交互系统通过3D扫描、CAD设计等方式将物理世界中的物体和系统进行数字化建模。这些数字模型被投射到虚拟环境中,用户可以通过手柄、头戴式设备等交互方式与数字模型进行操作和交互。这种技术不仅提高了用户对复杂系统的理解和操作能力,还广泛应用于各种领域,如工业制造、医疗保健和建筑设计等。

3D仿真交互系统的应用场景

工业制造:在工业制造中,3D仿真交互系统可以帮助企业对整个生产过程进行数字化建模和优化,从而提高生产效率和产品质量。

医疗保健:在医疗领域,3D仿真交互系统可以帮助医生更好地了解患者的病情,进行预测和规划,降低手术风险并提高手术成功率。

建筑设计:在建筑设计领域,3D仿真交互系统可以帮助建筑师更好地规划和设计建筑,提高施工效率和质量,减少人力和物力成本。

3D仿真交互系统的技术要点

数字建模技术:通过CAD设计软件或3D扫描仪等设备将物体和系统进行数字化建模。

虚拟现实技术:将数字模型投射到虚拟环境中,实现用户与数字模型的交互。

交互式操作技术:通过手柄、头戴式设备等交互方式,让用户与数字模型进行操作和交互。

数据处理和分析技术:对采集到的数据进行处理和分析,建立数学模型,从而对数字模型进行优化和预测。

厂区360全景图能够全方位展示厂区的各个角落和设施。这种技术通过使用全景相机或多个镜头设备对厂区进行360度无死角拍摄,然后将拍摄到的图像进行拼接和处理,最终生成一个完整的全景图像。参观者可以通过电脑或手机等设备,通过鼠标或触摸屏操作,实现360度自由旋转观看,仿佛置身于真实环境中。

应用场景和优势

招商引资:通过360度全景图,企业家可以详细展示厂区的环境、设施和入驻企业等信息,方便远程客商了解情况,提高招商效率。

工厂管理:在工厂管理中,360度全景图可以帮助管理人员实时监控设备运行状态、生产数据和物料消耗等信息,优化生产流程和管理决策。

安全培训和演练:通过VR全景图,可以进行设备维护、故障排查和安全培训等模拟演练,提高培训效果和安全性。

工艺仿真与优化:利用360度全景图可以模拟不同的生产方案和流程设计,预判潜在问题并进行优化,提升生产效率和降低停机时间。

远程协作:远程专家可以通过共享的VR全景视图参与到生产和维护过程中,实现高效协同工作。

技术原理和制作过程

三维建模与场景重构:使用三维建模技术对工厂的建筑结构、设备和生产线等进行高精度重建,形成逼真的虚拟环境。

全景拍摄与图像拼接:使用全景相机或多镜头设备对实际现场进行360度拍摄,然后通过图像拼接软件生成完整的全景图像。

实时监控与数据分析:集成物联网技术,实时显示设备运行状态、生产数据等信息,辅助决策优化。

交互式体验与模拟演练:用户可以通过VR头盔或其他交互设备在虚拟环境中自由移动和操作,进行安全培训和模拟演练。

我们是专业的3d渲染制作公司-工业产品设备3d模型,产品外观渲染图制作,专业制作三维渲染图的动画公司,为企业、政府机构、科教院校、设计院、工程建设安装施工、房地产、新能源环保行业、电器数码产品工业、智能家居、装饰公司、汽车智能系统、石油化工业、医疗器械设备、机械产品制造业、生产线企业、铁路采掘业、纺织业、船舶航空领域,提供一站式方案设计,打造企事业形象、提高品牌竞争力。

AR, VR, MR, and panoramic technology are four different technologies with their own characteristics in terms of interaction methods and application scenarios.

AR (Augmented Reality) technology overlays virtual information onto the real world through computer technology, allowing users to see virtual elements in the real environment. Typical applications of AR include the "AR red envelope" function, which scans real-world objects through a phone camera and displays relevant images, audio and video, and 3D models on the screen. The characteristics of AR technology are the combination of virtual and real, real-time interaction, which can enhance the visual effects and interactive experience of the real world.

VR (Virtual Reality) technology generates a completely virtual world through computers, allowing users to immerse themselves in it. VR devices such as head mounted displays (HMDs) combined with tracking systems provide real-time rendering, real space, and real interactive experiences. VR has a wide range of applications, including gaming, film and television, professional learning and training, tourism, manufacturing, and military fields. The characteristics of VR technology are immersion, interactivity, and imagination, which can simulate the visual, auditory, and tactile experiences of the real world.

MR (Mixed Reality) technology introduces real-world scene information into a virtual environment to achieve interactive feedback between the virtual world and the real world. The key to MR lies in its interaction with the real world and information acquisition, usually requiring an environment that can interact with various things in the real world. The applications of MR include synchronous surgical operations by doctors in two locations, as well as remote communication supported by 5G networks.

3D panoramic technology usually refers to 360 degree panoramic images or videos, which can provide a comprehensive viewing experience. Panoramic technology is commonly used in fields such as virtual tourism, real estate exhibitions, online education, etc., allowing users to explore virtual environments in an immersive manner. The combination of panoramic technology with AR and VR technology can provide a more immersive experience.

The 360 degree panoramic rotation of the mixing station model simulates an interactive 3D spatial scene through 360 degree panoramic technology, allowing users to view various parts and details of the mixing station from all angles and perspectives. This technology not only showcases the appearance and structure of the mixing station, but also allows users to control rotation, scaling, and other operations through a mouse or touch screen, achieving an immersive experience.

360 degree panoramic technology captures scenes from different angles using multiple high-definition cameras, and then concatenates these images into a complete panoramic image. Users can control the rotation and scaling of the viewing angle through a mouse or touch screen, achieving a 360 degree view without any blind spots. This technology has wide applications in industrial design, real estate display, tourist attraction introduction, and other fields, providing more intuitive and vivid display effects.

In the panoramic display of the mixing station model, 360 degree panoramic technology can be applied to the following aspects:

Appearance display: Display the appearance design and overall layout of the mixing station, allowing users to view various angles and details of the mixing station.

Internal structure: Through panoramic technology, users can view the internal structure of the mixing station and understand the location and function of each device.

Operation process: Display the operation and process flow of the mixing station to help users better understand its working principle.

Maintenance: Provide maintenance guidelines for mixing stations to help users understand how to perform daily maintenance and troubleshooting.

Through these applications, 360 degree panoramic technology can provide users with more intuitive and comprehensive mixing station information, improving user experience and efficiency.

We are a professional company specializing in 3D rendering production, product rendering, industrial model rendering, model rendering, and equipment rendering. We specialize in enterprise medical equipment, walkers, power equipment, products, mechanical equipment, chemical processes, installation, assembly, industrial electromechanical equipment, water conservancy equipment, petrochemical equipment, power engineering construction, elevators, construction, machinery, steel structure, bidding, architectural planning and design, industrial park buildings, environmental protection, photovoltaic power generation, and other fields. We provide professional 3D rendering design services and have extensive experience in 3D animation production and 3D product model appearance rendering.

360 degree panoramic rotation of a robotic arm model refers to the process of rotating the robotic arm model 360 degrees, allowing it to freely rotate in three-dimensional space and display various angles and details of the robotic arm. The 360 degree rotating robotic arm model is mainly used for display and interactive design. Through panoramic display, users can intuitively see the various parts and details of the robotic arm, facilitating design and optimization. For example, in industrial design, designers can adjust the structure and function of a robotic arm by rotating the model 360 degrees, ensuring its performance and safety in various work scenarios. The 360 degree rotating robotic arm model is typically implemented through computer graphics technology and virtual reality (VR) technology. Through software simulation, users can freely rotate the model in the virtual environment and view details from different angles. This technology not only improves the efficiency and accuracy of design, but also provides users with a more intuitive and interactive experience. In industrial design, 360 degree rotating robotic arm models are widely used in the design of robots and automation equipment. Designers can use this model to display in detail the various components and motion trajectories of the robotic arm, ensuring its stability and efficiency in complex working environments.

3D simulation interactive system is a technology that converts the physical world into a digital model and simulates and optimizes it in a virtual environment. It utilizes computer graphics, virtual reality technology, and interactive design techniques to enable users to interact and manipulate digital models. 3D simulation interactive systems typically include techniques such as digital modeling, virtual reality, and interactive operations. Through these techniques, users can observe, analyze, and optimize digital models in a virtual environment.

The 3D simulation interactive system digitally models objects and systems in the physical world through methods such as 3D scanning and CAD design. These digital models are projected into a virtual environment, and users can interact and manipulate them through interactive methods such as controllers and head mounted devices. This technology not only enhances users' understanding and operational capabilities of complex systems, but is also widely applied in various fields such as industrial manufacturing, healthcare, and architectural design.

Application scenarios of 3D simulation interactive system

Industrial manufacturing: In industrial manufacturing, 3D simulation interactive systems can help enterprises digitize and optimize the entire production process, thereby improving production efficiency and product quality.

Healthcare: In the medical field, 3D simulation interactive systems can help doctors better understand patients' conditions, make predictions and plans, reduce surgical risks, and improve surgical success rates.

Architectural Design: In the field of architectural design, 3D simulation interactive systems can help architects better plan and design buildings, improve construction efficiency and quality, and reduce labor and material costs.

Technical points of 3D simulation interactive system

Digital modeling technology: Digitally modeling objects and systems using CAD design software or 3D scanners and other equipment.

Virtual reality technology: projecting digital models into a virtual environment to enable interaction between users and digital models.

Interactive operation technology: Through interactive methods such as controllers and head mounted devices, users can operate and interact with digital models.

Data processing and analysis techniques: Processing and analyzing collected data, establishing mathematical models, and optimizing and predicting digital models.

The 360 degree panoramic view of the factory area can comprehensively display every corner and facility of the factory. This technology uses a panoramic camera or multiple lens devices to capture 360 degree panoramic images of the factory area, and then concatenates and processes the captured images to generate a complete panoramic image. Visitors can use devices such as computers or mobile phones, and operate through a mouse or touch screen to achieve 360 degree free rotation and viewing, as if they are in a real environment.

Application scenarios and advantages

Investment Promotion: Through a 360 degree panoramic view, entrepreneurs can display detailed information about the environment, facilities, and settled enterprises in the factory area, making it convenient for remote merchants to understand the situation and improve investment promotion efficiency.

Factory management: In factory management, a 360 degree panoramic view can help managers monitor equipment operation status, production data, and material consumption in real time, optimize production processes, and make management decisions.

Safety training and drills: Through VR panoramic images, simulation drills such as equipment maintenance, troubleshooting, and safety training can be conducted to improve training effectiveness and safety.

Process simulation and optimization: By using 360 degree panoramic images, different production plans and process designs can be simulated, potential problems can be predicted and optimized, improving production efficiency and reducing downtime.

Remote collaboration: Remote experts can participate in production and maintenance processes through shared VR panoramic views, achieving efficient collaborative work.

Technical principles and manufacturing process

3D modeling and scene reconstruction: Using 3D modeling technology to achieve high-precision reconstruction of the building structure, equipment, and production line of the factory, forming a realistic virtual environment.

Panoramic shooting and image stitching: Use a panoramic camera or multi lens device to capture 360 degrees of the actual scene, and then generate a complete panoramic image through image stitching software.

Real time monitoring and data analysis: Integrated with IoT technology, real-time display of device operating status, production data, and other information to assist in decision-making optimization.

Interactive experience and simulation exercises: Users can freely move and operate in a virtual environment through VR helmets or other interactive devices for safety training and simulation exercises.

We are a professional 3D rendering production company specializing in the production of industrial product equipment 3D models, product appearance rendering, and animation. We provide one-stop solution design for enterprises, government agencies, science and education institutions, design institutes, engineering construction and installation, real estate, new energy and environmental protection industries, electrical and digital product industries, smart homes, decoration companies, automotive intelligent systems, petrochemical industry, medical equipment, mechanical product manufacturing, production line enterprises, railway mining industry, textile industry, shipbuilding and aviation fields, creating corporate image and enhancing brand competitiveness.

QQ咨询

QQ咨询

189 5158 0154

189 5158 0154

在线留言

在线留言