↓↓下拉很多 ➟➟微信☎

搅拌设备3D渲染图:

车间模型全景360旋转:

拌合站模型全景360旋转:

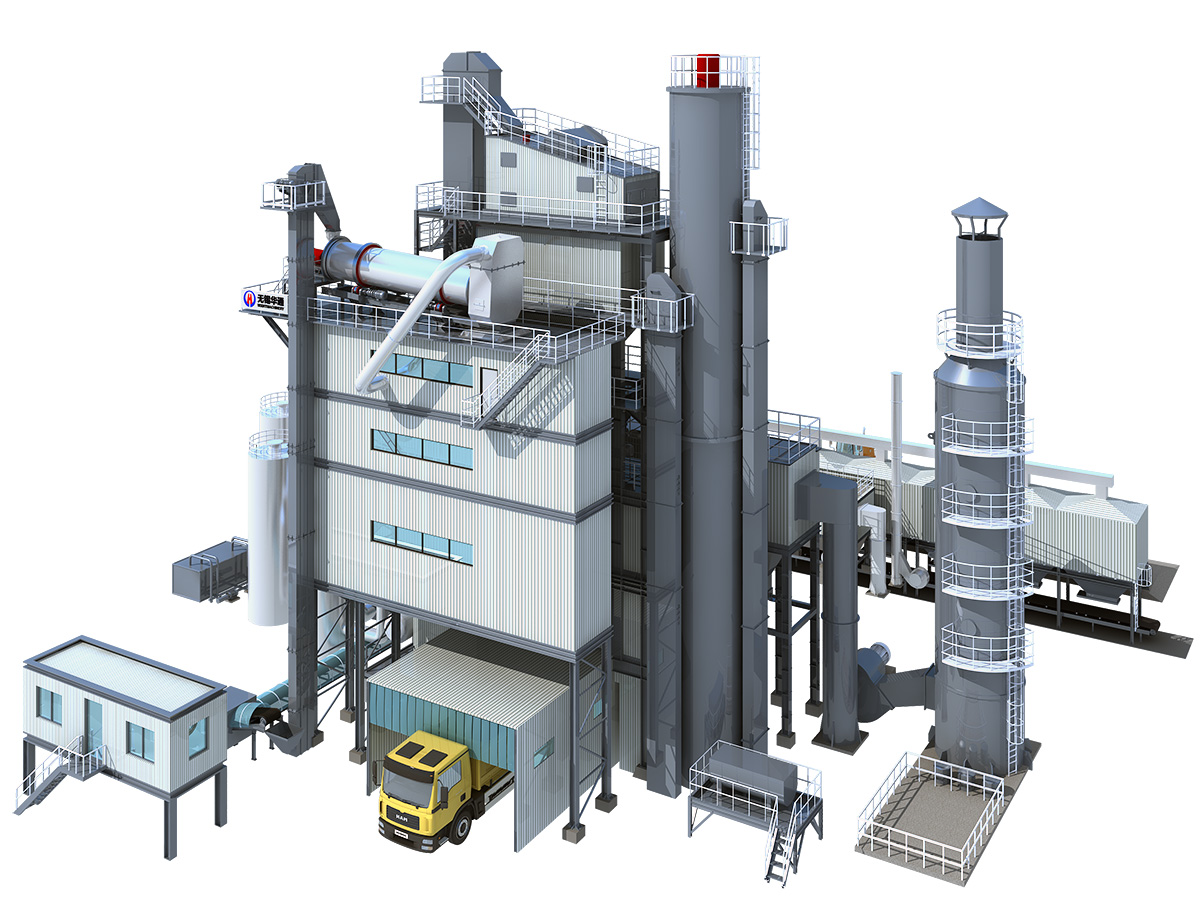

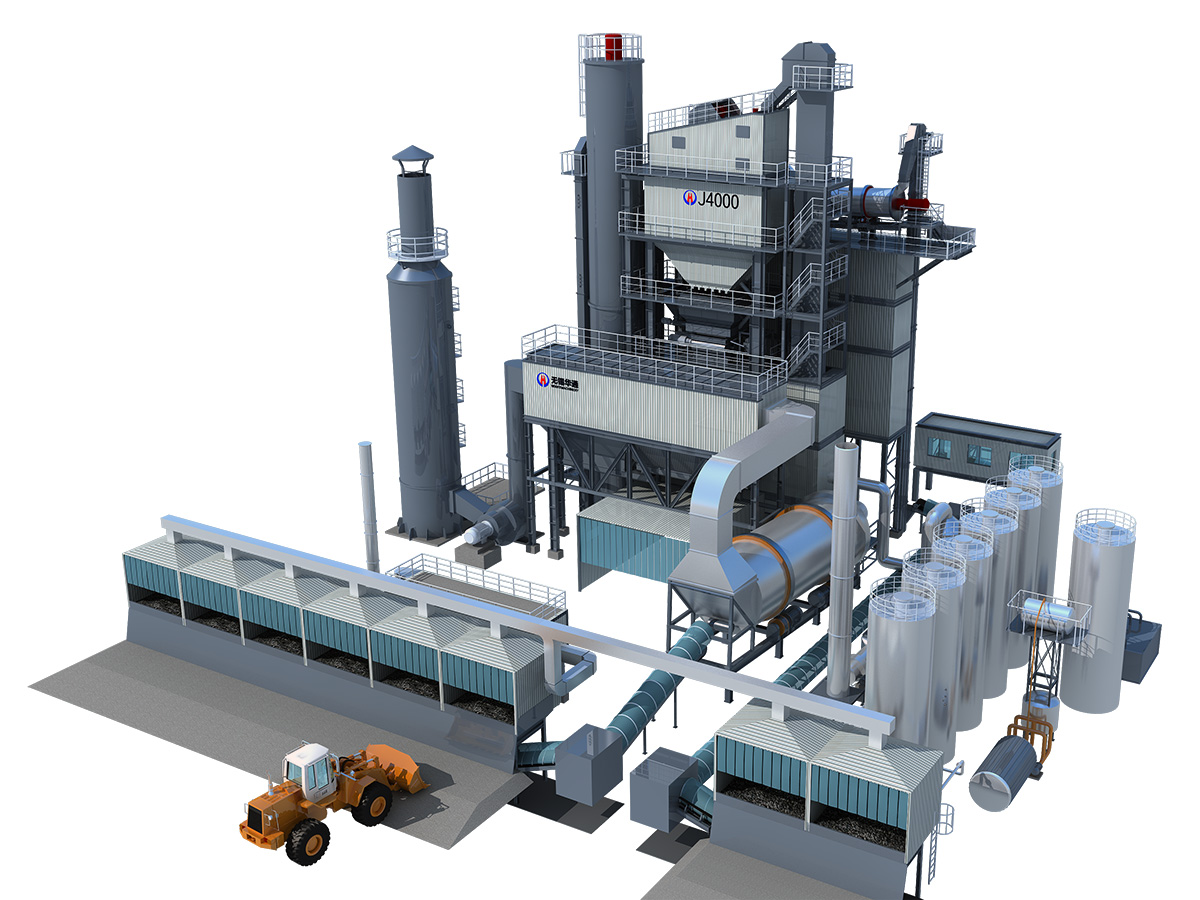

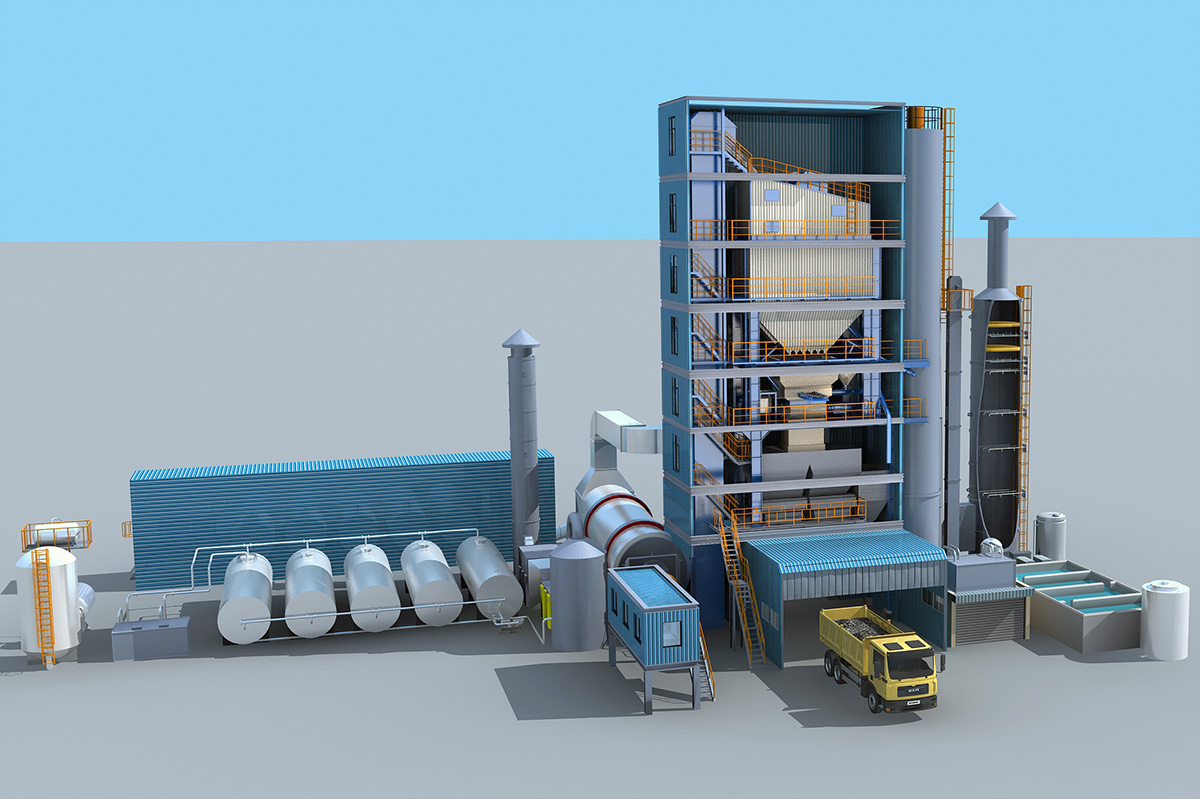

沥青搅拌站设备3D模型渲染图:

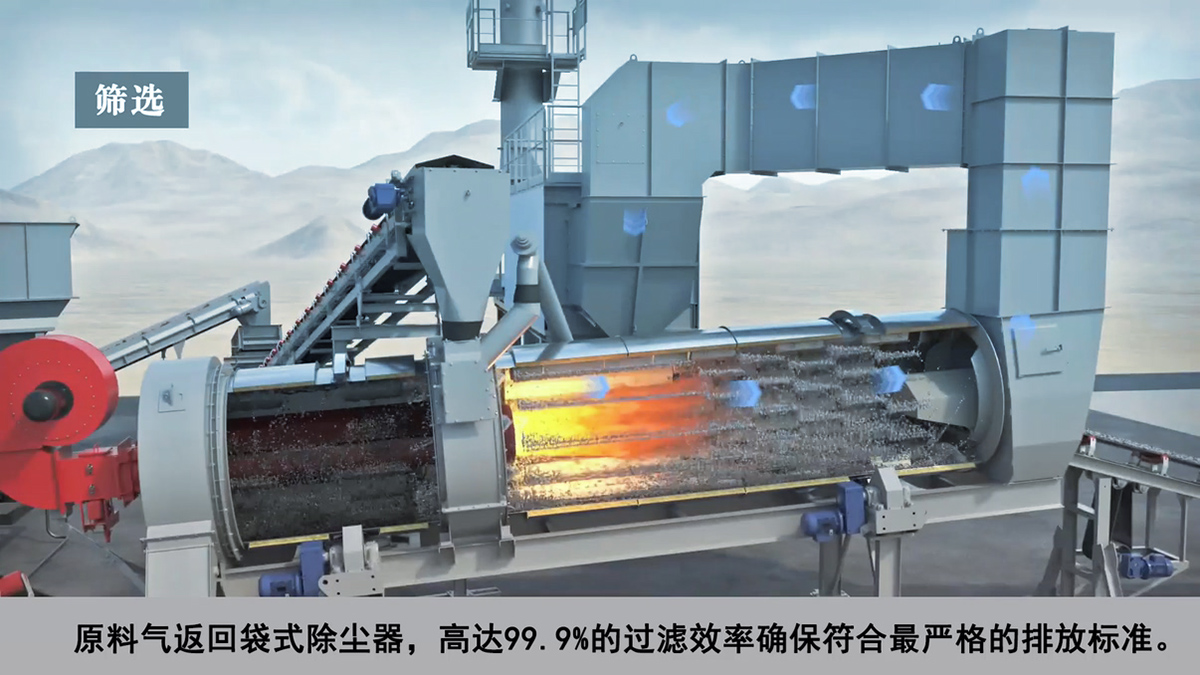

沥青搅拌站滚筒结构燃烧除尘3D防真渲染图:

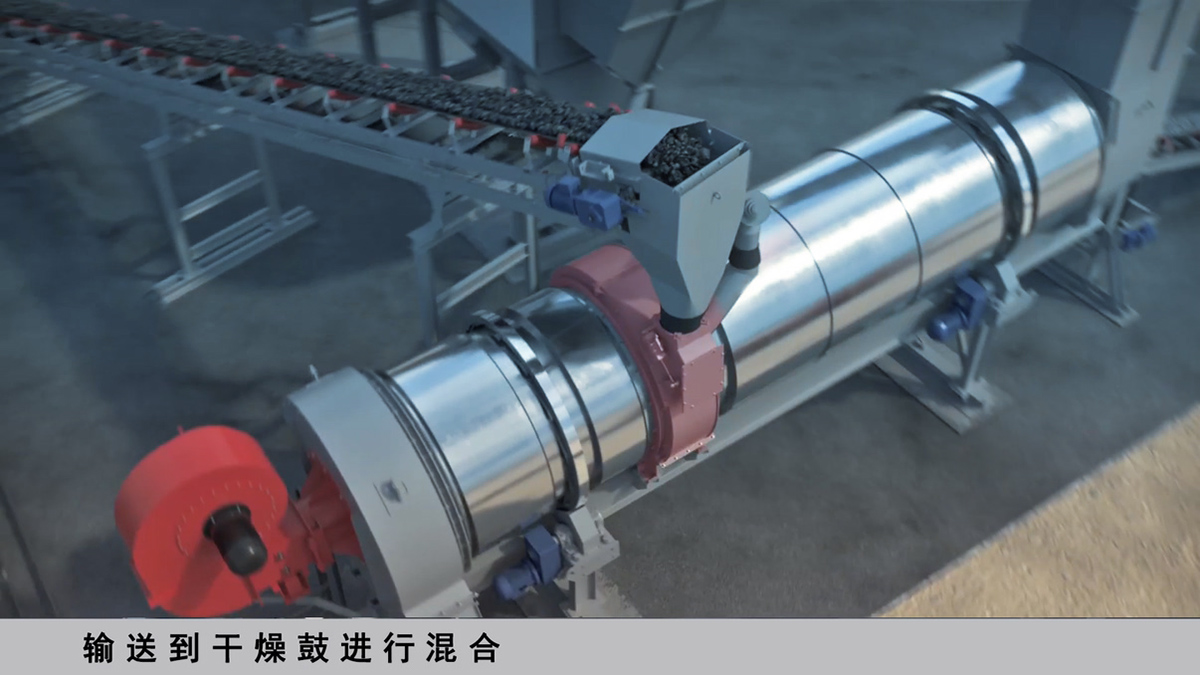

沥青搅拌站滚筒传输防真动画渲染图:

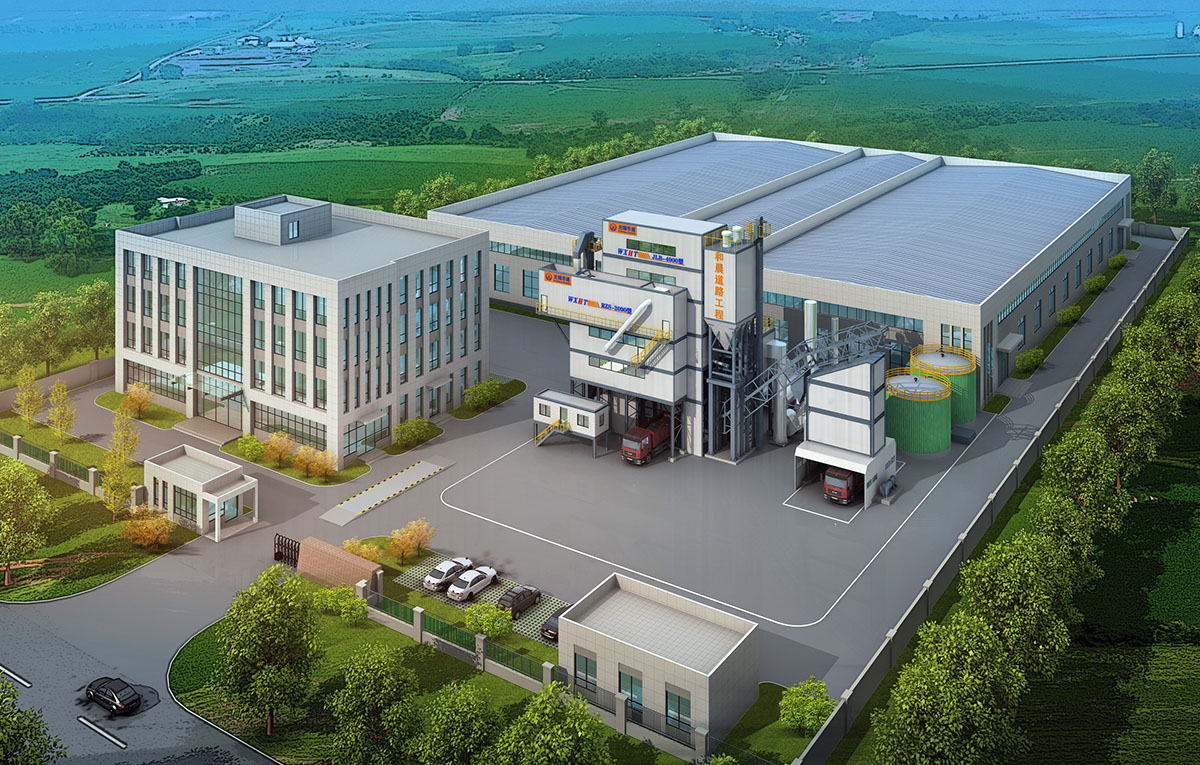

水泥混凝土搅拌站企业规划设计3D渲染效果图:

沥青混合料搅拌设备内部结构3D渲染效果图:

环保绿色混凝土搅拌站企业规划3D效果图渲染:

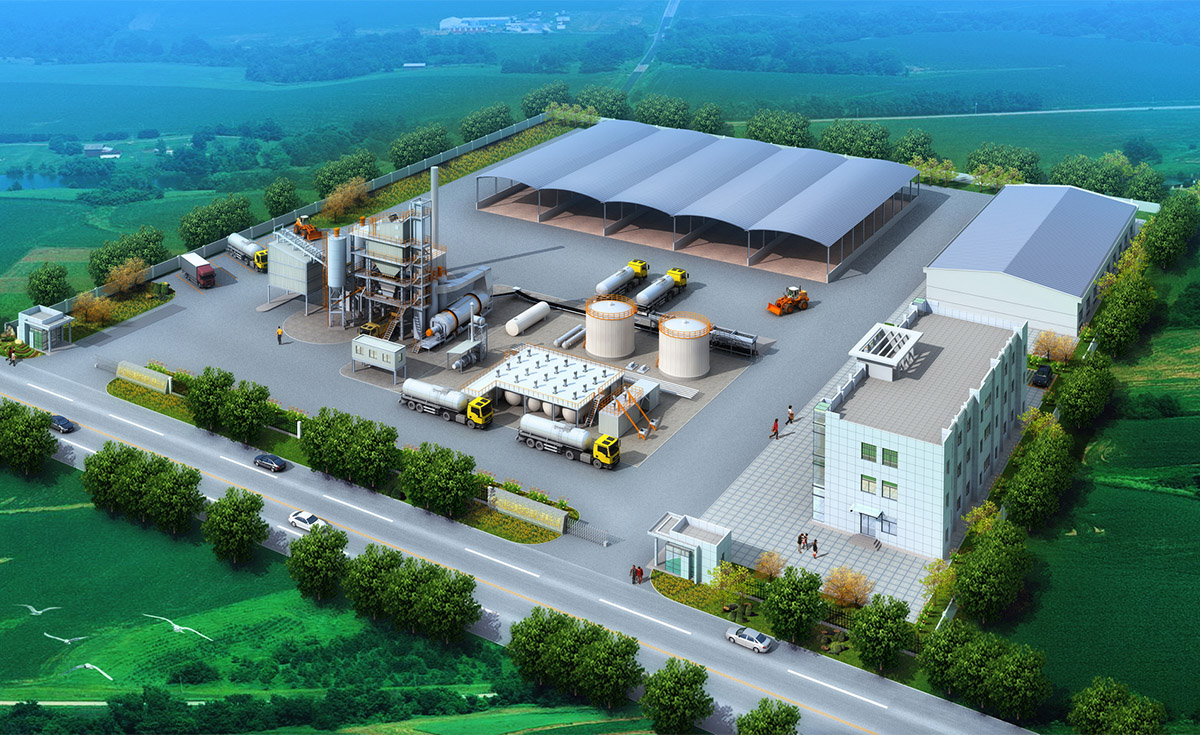

热再生设备厂区设计方案布置三维渲染图:

沥青混凝土拌合站的工艺流程3D渲染图:

******** 点击 返回主页_看更多案例 ********

搅拌设备3D渲染图是将搅拌设备的三维模型渲染成具有真实感的二维图像。这种技术广泛应用于工程设计和制造领域,可以帮助设计师和工程师在产品实际生产之前,通过计算机模拟出产品的外观、材质和光照效果,从而更好地评估设计方案的可行性和美观性。

搅拌设备3D渲染图的应用在产品设计领域,3D渲染图可以帮助预测产品的外观和功能,使设计师能够更好地了解产品设计,并提供给客户更直观的设计展示。3D渲染技术可以快速生成高质量的图像,使设计师和客户能够更快地了解和决策项目。通过模拟设计,可以减少项目的重复设计和建造,从而节省时间和成本。3D渲染技术可以帮助设计师更好地了解项目的细节和效果,从而提高设计质量。清晰和真实的渲染图像可以使设计师和客户之间的沟通更加清晰和明确。

沥青搅拌站设备3D模型渲染图是通过三维建模软件创建的沥青搅拌站设备的视觉表现图,详细展示了设备的各个组成部分及其工作状态。这些组成部分包括配料系统、干燥系统、燃烧系统、热料提升系统、筛分系统、热料储存系统、称量系统、搅拌系统、除尘系统、粉料供给系统、粉尘回收系统、成品料提升储存系统、气动系统、控制系统和沥青储存供给系统等。通过这些组成部分的详细展示,可以清晰地了解沥青搅拌站的工作原理和操作流程。

例如,配料系统通过电子秤称量各种砂石料和粉料,干燥系统通过优化设计的干燥筒提高效率,避免骨料过热,筛分系统确保粉料的分选精度,搅拌系统通过强制式搅拌实现均匀混合等23。这些细节在3D模型渲染图中都有详细的展示。

此外,沥青搅拌站设备3D模型渲染图的应用场景包括:

产品展示:在产品发布会或展览会上展示设备的外观和功能。

生产培训:用于新员工培训,帮助理解设备的操作和维护。

市场推广:通过三维动画展示设备的生产流程,提升客户对产品的信任度和购买欲望。

内部沟通:在项目团队内部进行技术交流和方案讨论时,提供直观的视觉参考。

搅拌站滚筒燃烧除尘3D仿真图是一种用于展示搅拌站滚筒燃烧过程中除尘系统的三维模型和仿真动画。这种仿真图通常包括引风机、旋风分离器和布袋除尘器等主要组成部分,用于模拟滚筒燃烧过程中粉尘的收集和处理过程。

搅拌站滚筒燃烧除尘系统的主要组成部分及其功能

引风机:负责将含有粉尘的空气吸入除尘系统,提供必要的风压。

旋风分离器:通过离心力的作用,将大颗粒粉尘从气流中分离出来。

布袋除尘器:利用布袋过滤技术,进一步净化气流中的微小粉尘颗粒。

沥青搅拌站的主要组成部分及其功能

沥青搅拌站主要由以下系统组成:

配料系统:负责各种原材料的配比。

干燥系统:对原材料进行加热和干燥。

燃烧系统:提供热源,通常使用燃烧器。

热料提升系统:将干燥后的材料提升至搅拌滚筒。

振动筛:对材料进行筛选。

热料贮存仓:储存热料。

称量搅拌系统:将各种材料按比例混合。

沥青供给系统:提供沥青。

粉料供给系统:提供其他粉状材料。

除尘系统:处理搅拌过程中产生的粉尘。

成品料仓:储存最终产品。

控制系统:对整个设备进行自动化控制。

燃烧器是沥青搅拌站的核心部件之一,分为以下几种类型:天然气燃烧器、石油液化气燃烧器、高炉煤气燃烧器、焦炉煤气燃烧器、轻烃燃气燃烧器、煤气发生炉、煤粉燃烧器、柴油、重油、甲醇燃烧器等。这些燃烧器根据所选燃料的不同,具有不同的性能和适用场景,选择合适的燃烧器可以提高设备的效率和稳定性。

3D仿真渲染图用于展示沥青搅拌站滚筒结构、燃烧系统和除尘系统的详细设计和工作状态。这种仿真渲染图可以帮助用户更好地理解设备的内部结构和运行机制,从而进行更有效的维护和操作。

搅拌站滚筒燃烧过程中产生的粉尘通过引风机进入除尘系统。首先经过旋风分离器,大颗粒粉尘被分离出来;随后,气流进入布袋除尘器,微小粉尘被布袋捕捉,净化后的空气排出系统。整个过程有效减少了粉尘排放,保护环境和操作人员健康。

搅拌站滚筒燃烧除尘系统广泛应用于各种工业生产中,特别是在混凝土搅拌站、化工厂等场所。其重要性在于能够有效减少粉尘排放,符合环保要求,保护环境和操作人员的健康。通过3D仿真图,可以直观地展示除尘系统的运行过程和效果,便于设计和维护。

沥青搅拌站传输动画展示沥青搅拌站工作原理和操作流程的视觉呈现。这种动画通常用于解释沥青搅拌站的工作流程,帮助用户更好地理解其工作机制。沥青搅拌站传输动画通常包括以下内容:

工作原理:展示沥青搅拌站的主要组成部分,如冷料仓、干燥筒、燃烧室、热料仓、振动筛、搅拌锅等,并解释它们各自的功能和作用。

操作流程:通过动画演示,展示从原料进入搅拌站到成品沥青输出的全过程,包括原料的输送、加热、搅拌等环节。

设备细节:展示搅拌站的各个部件如何协同工作,以及关键部件的工作原理和操作细节。

沥青搅拌站传输动画主要应用于以下场景:

技术培训:帮助新员工快速理解沥青搅拌站的工作原理和操作流程。

设备维护:帮助维护人员了解设备的内部结构,便于日常维护和故障排查。

销售展示:向客户展示沥青搅拌站的高效性和可靠性,提升产品竞争力。

工程案例:通过实际案例展示沥青搅拌站在不同工程项目中的应用效果。

水泥混凝土搅拌站企业规划设计3D渲染效果图用于展示搅拌站的整体布局、设备和工艺流程作用和重要性:

直观展示:3D渲染效果图能够以直观的三维视角展示搅拌站的全貌,包括建筑分布、道路规划、设备布局等,帮助投资者、合作伙伴和管理团队快速把握项目的宏观架构。

优化设计:在项目规划初期,通过3D渲染效果图可以评估不同布局方案对生产流程效率的影响,选择最优设计方案,避免实际建设中的成本增加和效率低下问题。

增强信心:精细建模和动画演示可以生动呈现原材料从进场到成品输出的整个工艺流程,增强客户对企业生产能力和产品质量的信心。

吸引投资:通过模拟不同天气和时间场景,营造真实的环境氛围,增强展示的感染力和吸引力,帮助企业吸引更多的投资和合作机会。

3D渲染效果图的应在项目规划初期,用于评估不同布局方案。展示搅拌设备、输送系统、配料装置等,帮助客户详细了解设备的关键部件和技术创新点。作为直观有效的教学工具,帮助新员工快速熟悉工作流程。通过场景模拟,增强展示的感染力和吸引力,吸引更多的投资和合作机会。

环保型绿色搅拌站企业的规划3D效果图渲染主要包括以下几个方面:

场区整体规划:环保型搅拌站的场区规划是关键环节,需要合理布局,力求美观大方和生产高效。预留绿化用地,合理规划辅助环保设施的空间,如砂石分离机、浆水回收池、制砖机等。

设备采购和管理:选择符合环保标准的设备,如搅拌机、输送带、水泵等。设备的采购需考虑其成本和质量,确保符合环保要求。同时,建立健全的环保管理制度,明确各级人员的职责和权限,加强环保培训和宣传教育,提高员工的环保意识和素质。

噪音和粉尘控制:对搅拌站内的噪音源进行排查,加装隔音设施,定期维护设备以减少噪音排放。对砂石料场进行封闭处理,采用喷雾等抑尘措施,减少粉尘泄露。加强厂区清洁工作,定期清扫道路和场地。

废水、废渣处理:建立废水收集和处理系统,对废水进行分类处理和回收利用。对废渣进行分类收集和处理,配合相关部门进行无害化处理。加强监测和监管,确保废水、废渣处理设施的正常运行。

资源循环利用:采用砂石分离和浆水回收设备,将清洗废水中的砂、石分离并回收利用,实现废料的零排放。收集雨水用于混凝土生产,节约地下水资源。引进废弃混凝土制砖机,解决废弃混凝土的污染和浪费问题。

智能化管理:配备ERP管理系统和GPS管理系统,提高管理效率和调度安排的合理性。采用气浮溜槽送料方式和砂浆裹石的施工工艺,降低能耗。

通过以上规划3D设计措施,环保型绿色搅拌站企业能够实现噪音和粉尘的有效控制,废水、废渣的合理处理和资源循环利用,提高生产效率和环保管理水平,推动企业的可持续发展。

我们是专业3d渲染制作,产品渲染图制作,工业模型渲染,模型渲染,设备渲染图制作公司,擅长企业医疗器械、助行器、电力设备、产品、机械设备、化工工艺、安装、组装、工业机电设备、水利设备、石化设备、电力工程建设、电梯、施工、机械、钢构、投标、建筑规划设计、工业园区厂房、环保、光伏发电等领域,提供专业的3d渲染设计服务,并拥有大量3D动画制作+3d产品模型外观渲染图制作经验。

热再生设备三维渲染图是用于展示再生某些工业过程中产生的燃气废热,从而减少废气排放和能源浪费。它通常由燃烧器、再生炉、热风炉和废气处理系统等组成。

热再生设备3D渲染图可以直观展示出通过传导、对流和辐射三种方式来加热再生炉中的热媒物质,使其达到所需温度。热媒材料在高温下与废气进行热交换,将废气中的热量吸收并传递给下一次的生产过程使用。废气经过净化后得到充分利用,不再对环境造成污染。

热再生设备3D渲染图设计的类型和应用场景

回转窑再生炉:适用于大规模工业处理,如石化、化工、废水处理等行业,具有处理能力强、自动化程度高的优点,但能耗较高,初始投资成本大。

流化床再生炉:适用于中小规模的活性炭再生,尤其是对粒径均匀的废活性炭,具有高效、温度分布均匀的优点,但对设备操作要求高。

电加热再生炉:适用于实验室或小规模再生,具有加热精确、温控灵活的优点,但再生效率较低,能耗较高。

渲染图上可以体现热再生设备优势和应用领域

环保节能:热再生设备可大幅降低氮氧化物、二氧化硫、颗粒物等有害物质的排放量,达到90%以上,减少企业对环境的危害。

利润增长:通过成本控制和资源再利用,提高生产效率,减少能源消耗,增加企业利润。

操作简便:设备智能化程度高,节省人力成本与时间。

技术成熟:已被广泛应用于钢铁、炼油、化工、建筑等行业,稳定性较强。

拌合站的工艺流程3D渲染图展示了拌合站的主要设备和工艺流程包括:

骨料称量:所需骨料包括砂石料,由汽车运至厂区,再分别用装载机装入密闭骨料仓,通过皮带输送机输送到骨料过渡仓,最终落入混凝土搅拌机内搅拌。

粉料称量:所需的粉料如水泥、粉煤灰等,由密封罐车运至厂区,通过螺旋输送机输送到称量斗进行称量,然后滑入混凝土搅拌机。

水称量:所需的水由水泵抽入称量箱称量,然后喷入搅拌机。

外加剂称量:所需的添加剂由自吸泵抽至称量箱称量,然后喷入混凝土搅拌机。

混凝土搅拌:骨料、粉料、水和外加剂按设定时间投入混凝土搅拌机,通过双道螺旋叶片进行搅拌,搅拌完成后推到运输车。

3D渲染图通过精细建模和高清晰度的图像展示设备的外观设计、结构特点以及内部工作原理。通过动画演示或交互功能,可以生动地呈现原材料从进场、配料、搅拌到成品输出的整个工艺流程。这对于客户来说,能够更深入地了解产品的生产过程和质量控制环节,增强对企业生产能力和产品质量的信心;

我们是专业的3d渲染制作公司-工业产品设备3d模型,产品外观渲染图制作,专业制作三维渲染图的动画公司,为企业、政府机构、科教院校、设计院、工程建设安装施工、房地产、新能源环保行业、电器数码产品工业、智能家居、装饰公司、汽车智能系统、石油化工业、医疗器械设备、机械产品制造业、生产线企业、铁路采掘业、纺织业、船舶航空领域,提供一站式方案设计,打造企事业形象、提高品牌竞争力。

The 3D rendering of mixing equipment is to render the three-dimensional model of the mixing equipment into a realistic two-dimensional image. This technology is widely used in the fields of engineering design and manufacturing, which can help designers and engineers simulate the appearance, materials, and lighting effects of products through computer simulation before actual production, thereby better evaluating the feasibility and aesthetics of design solutions.

The application of 3D rendering of mixing equipment in the field of product design can help predict the appearance and function of products, enabling designers to better understand product design and provide customers with more intuitive design displays. 3D rendering technology can quickly generate high-quality images, enabling designers and clients to understand and make decisions about projects more quickly. By simulating design, it is possible to reduce the repetitive design and construction of projects, thereby saving time and costs. 3D rendering technology can help designers better understand the details and effects of a project, thereby improving design quality. Clear and realistic rendered images can make communication between designers and clients clearer and more explicit.

The 3D model rendering of asphalt mixing plant equipment is a visual representation created through 3D modeling software, which details the various components and working status of the equipment. These components include batching system, drying system, combustion system, hot material lifting system, screening system, hot material storage system, weighing system, mixing system, dust removal system, powder supply system, dust recovery system, finished material lifting and storage system, pneumatic system, control system, and asphalt storage and supply system. Through the detailed display of these components, one can clearly understand the working principle and operation process of the asphalt mixing plant.

For example, the batching system uses electronic scales to weigh various sand and gravel materials and powders, the drying system improves efficiency by optimizing the design of the drying cylinder to avoid overheating of the aggregates, the screening system ensures the sorting accuracy of the powders, and the mixing system achieves uniform mixing through forced mixing. These details are detailed in the 3D model rendering.

In addition, the application scenarios for rendering 3D models of asphalt mixing plant equipment include:

Product Display: Showcase the appearance and functionality of the equipment at product launches or exhibitions.

Production training: used for new employee training to help understand equipment operation and maintenance.

Market promotion: By displaying the production process of the equipment through 3D animation, we aim to enhance customers' trust and purchasing desire for the product.

Internal communication: Provide visual references for technical exchanges and scheme discussions within the project team.

The 3D simulation diagram of drum combustion dust removal in a mixing plant is a three-dimensional model and simulation animation used to demonstrate the dust removal system during the drum combustion process in a mixing plant. This type of simulation diagram usually includes the main components such as induced draft fan, cyclone separator, and bag filter, used to simulate the collection and treatment process of dust during drum combustion.

The main components and functions of the drum combustion dust removal system in the mixing plant

Induced draft fan: responsible for drawing air containing dust into the dust removal system and providing necessary air pressure.

Cyclone separator: Separate large particles of dust from the airflow through the action of centrifugal force.

Bag filter: using bag filtration technology to further purify small dust particles in the airflow.

The main components and functions of an asphalt mixing plant

The asphalt mixing plant mainly consists of the following systems:

Ingredient system: responsible for the proportioning of various raw materials.

Drying system: Heating and drying of raw materials.

Combustion system: provides a heat source, usually using a burner.

Hot material lifting system: Lift the dried material to the mixing drum.

Vibration screen: Screen materials.

Hot material storage warehouse: stores hot materials.

Weighing and mixing system: Mix various materials in proportion.

Asphalt supply system: Provide asphalt.

Powder supply system: Provide other powdered materials.

Dust removal system: deals with the dust generated during the mixing process.

Finished product silo: stores the final product.

Control system: Automated control of the entire equipment.

Burner is one of the core components of asphalt mixing plant, which can be divided into the following types: natural gas burner, liquefied petroleum gas burner, blast furnace gas burner, coke oven gas burner, light hydrocarbon gas burner, gas generator, coal powder burner, diesel, heavy oil, methanol burner, etc. These burners have different performance and applicable scenarios depending on the selected fuel. Choosing the appropriate burner can improve the efficiency and stability of the equipment.

The 3D simulation rendering is used to display the detailed design and working status of the drum structure, combustion system, and dust removal system of the asphalt mixing plant. This simulation rendering can help users better understand the internal structure and operating mechanism of the device, thereby enabling more effective maintenance and operation.

The dust generated during the drum combustion process in the mixing plant enters the dust removal system through the induced draft fan. Firstly, after passing through the cyclone separator, large particle dust is separated out; Subsequently, the airflow enters the bag filter, where tiny dust is captured by the bag and the purified air is discharged from the system. The entire process effectively reduced dust emissions, protecting the environment and the health of operators.

The drum combustion dust removal system of mixing plants is widely used in various industrial productions, especially in concrete mixing plants, chemical plants and other places. Its importance lies in effectively reducing dust emissions, meeting environmental requirements, and protecting the environment and the health of operators. Through 3D simulation diagrams, the operation process and effectiveness of the dust removal system can be visually displayed, making it easy to design and maintain.

Visual presentation of the working principle and operation process of asphalt mixing plant transmission animation. This animation is commonly used to explain the workflow of asphalt mixing plants and help users better understand their working mechanisms. The animation of asphalt mixing plant transportation usually includes the following content:

Working principle: Display the main components of the asphalt mixing plant, such as the cold bin, drying drum, combustion chamber, hot bin, vibrating screen, mixing pot, etc., and explain their respective functions and roles.

Operation process: Through animation demonstration, demonstrate the entire process from raw material entering the mixing plant to finished asphalt output, including the transportation, heating, mixing and other links of raw materials.

Equipment details: Show how the various components of the mixing plant work together, as well as the working principles and operational details of key components.

Asphalt mixing plant transmission animation is mainly applied in the following scenarios:

Technical training: Help new employees quickly understand the working principles and operating procedures of asphalt mixing plants.

Equipment maintenance: Help maintenance personnel understand the internal structure of the equipment, facilitating daily maintenance and troubleshooting.

Sales display: Show customers the efficiency and reliability of asphalt mixing plants, enhance product competitiveness.

Engineering case: Demonstrate the application effect of asphalt mixing plants in different engineering projects through practical cases.

The 3D rendering rendering rendering of the planning and design of cement concrete mixing plant enterprises is used to showcase the overall layout, equipment, and process flow of the mixing plant, as well as its importance and significance

Intuitive display: 3D rendering renderings can present the overall picture of the mixing plant from an intuitive 3D perspective, including building distribution, road planning, equipment layout, etc., helping investors, partners, and management teams quickly grasp the macro architecture of the project.

Optimization design: In the early stages of project planning, 3D rendering renderings can be used to evaluate the impact of different layout schemes on production process efficiency, select the optimal design scheme, and avoid cost increases and low efficiency issues in actual construction.

Enhance confidence: Fine modeling and animated demonstrations can vividly present the entire process of raw materials from entry to finished product output, enhancing customers' confidence in the company's production capacity and product quality.

Attracting investment: By simulating different weather and time scenarios, creating a realistic environmental atmosphere, enhancing the infectivity and attractiveness of the display, and helping enterprises attract more investment and cooperation opportunities.

The 3D rendering effect should be used in the early stages of project planning to evaluate different layout schemes. Showcase mixing equipment, conveying systems, batching devices, etc., to help customers gain a detailed understanding of the key components and technological innovations of the equipment. As an intuitive and effective teaching tool, it helps new employees quickly familiarize themselves with the workflow. By simulating scenarios, enhance the infectivity and attractiveness of the display, and attract more investment and cooperation opportunities.

The 3D rendering of planning for environmentally friendly green mixing plant enterprises mainly includes the following aspects:

Overall planning of the site: The planning of the environmentally friendly mixing plant site is a key link that requires a reasonable layout, striving for beauty, elegance, and high production efficiency. Reserve green land and plan the space for auxiliary environmental protection facilities reasonably, such as sand and gravel separators, slurry water recovery tanks, brick making machines, etc.

Equipment procurement and management: Select equipment that meets environmental standards, such as mixers, conveyor belts, water pumps, etc. The procurement of equipment needs to consider its cost and quality to ensure compliance with environmental requirements. At the same time, establish a sound environmental management system, clarify the responsibilities and authorities of personnel at all levels, strengthen environmental training and publicity education, and improve employees' environmental awareness and quality.

Noise and dust control: Investigate the sources of noise in the mixing plant, install sound insulation facilities, and regularly maintain equipment to reduce noise emissions. The sand and gravel quarry shall be closed, and dust suppression measures such as spray shall be taken to reduce dust leakage. Strengthen the cleaning work in the factory area and regularly clean the roads and site.

Wastewater and waste residue treatment: Establish a wastewater collection and treatment system, classify and recycle wastewater. Classify and collect waste residue, and cooperate with relevant departments to carry out harmless treatment. Strengthen monitoring and supervision to ensure the normal operation of wastewater and waste treatment facilities.

Resource recycling: Using sand and stone separation and slurry water recovery equipment, the sand and stone in the cleaning wastewater are separated and recycled, achieving zero discharge of waste materials. Collect rainwater for concrete production and save groundwater resources. Introduce waste concrete brick making machines to solve the pollution and waste problems of waste concrete.

Intelligent management: equipped with ERP management system and GPS management system to improve management efficiency and the rationality of scheduling arrangements. Adopting the air flotation chute feeding method and the construction technology of mortar wrapped stone to reduce energy consumption.

Through the above planned 3D design measures, environmentally friendly green mixing plant enterprises can achieve effective control of noise and dust, reasonable treatment of wastewater and waste residue, and resource recycling, improve production efficiency and environmental management level, and promote the sustainable development of enterprises.

We are a professional company specializing in 3D rendering production, product rendering, industrial model rendering, model rendering, and equipment rendering. We specialize in enterprise medical equipment, walkers, power equipment, products, mechanical equipment, chemical processes, installation, assembly, industrial electromechanical equipment, water conservancy equipment, petrochemical equipment, power engineering construction, elevators, construction, machinery, steel structure, bidding, architectural planning and design, industrial park buildings, environmental protection, photovoltaic power generation, and other fields. We provide professional 3D rendering design services and have extensive experience in 3D animation production and 3D product model appearance rendering.

The 3D rendering of thermal regeneration equipment is used to display the gas waste heat generated during certain industrial processes, thereby reducing exhaust emissions and energy waste. It usually consists of a burner, regeneration furnace, hot blast stove, and exhaust gas treatment system.

The 3D rendering of the thermal regeneration equipment can visually display the heating of the heat medium material in the regeneration furnace through conduction, convection, and radiation to achieve the desired temperature. Heat medium materials exchange heat with exhaust gas at high temperatures, absorbing and transferring heat from the exhaust gas to the next production process. After purification, the exhaust gas is fully utilized and no longer causes pollution to the environment.

Types and application scenarios of 3D rendering design for thermal regeneration equipment

Rotary kiln regeneration furnace: suitable for large-scale industrial treatment, such as petrochemical, chemical, wastewater treatment and other industries, with the advantages of strong treatment capacity and high degree of automation, but high energy consumption and initial investment cost.

Fluidized bed regeneration furnace: suitable for small and medium-sized activated carbon regeneration, especially for uniformly sized waste activated carbon. It has the advantages of high efficiency and uniform temperature distribution, but requires high equipment operation.

Electric heating regeneration furnace: suitable for laboratory or small-scale regeneration, with the advantages of precise heating and flexible temperature control, but with low regeneration efficiency and high energy consumption.

The rendered image can reflect the advantages and application areas of thermal regeneration equipment

Environmental protection and energy conservation: Thermal regeneration equipment can significantly reduce the emissions of harmful substances such as nitrogen oxides, sulfur dioxide, and particulate matter by over 90%, reducing the harm of enterprises to the environment.

Profit growth: By controlling costs and reusing resources, we can improve production efficiency, reduce energy consumption, and increase corporate profits.

Easy to operate: The device has a high degree of intelligence, saving labor costs and time.

Mature technology: It has been widely used in industries such as steel, refining, chemical, and construction, with strong stability.

The 3D rendering of the process flow of the mixing station shows the main equipment and process flow of the mixing station, including:

Aggregate weighing: The required aggregates include sand and gravel, which are transported by truck to the factory area, and then loaded into closed aggregate bins by loaders. They are transported to the aggregate transition bin by a belt conveyor and finally mixed in a concrete mixer.

Powder weighing: The required powders such as cement, fly ash, etc. are transported to the factory area by sealed tank trucks, conveyed to the weighing hopper by a screw conveyor for weighing, and then slid into the concrete mixer.

Water weighing: The required water is pumped into the weighing box by a water pump for weighing, and then sprayed into the mixer.

Additive weighing: The required additives are pumped by a self-priming pump into a weighing box for weighing, and then sprayed into a concrete mixer.

Concrete mixing: Aggregates, powders, water, and admixtures are added to the concrete mixer according to the set time, mixed by double spiral blades, and pushed to the transport vehicle after mixing is completed.

3D rendering images showcase the appearance design, structural features, and internal working principles of the device through fine modeling and high-definition images. Through animated demonstrations or interactive functions, the entire process of raw materials from entry, batching, mixing to finished product output can be vividly presented. For customers, this can provide a deeper understanding of the production process and quality control links of the product, enhancing their confidence in the company's production capacity and product quality;

We are a professional 3D rendering production company specializing in the production of industrial product equipment 3D models, product appearance rendering, and animation. We provide one-stop solution design for enterprises, government agencies, science and education institutions, design institutes, engineering construction and installation, real estate, new energy and environmental protection industries, electrical and digital product industries, smart homes, decoration companies, automotive intelligent systems, petrochemical industry, medical equipment, mechanical product manufacturing, production line enterprises, railway mining industry, textile industry, shipbuilding and aviation fields, creating corporate image and enhancing brand competitiveness.

QQ咨询

QQ咨询

189 5158 0154

189 5158 0154

在线留言

在线留言