↓↓下拉很多 ➟➟微信☎

车间研磨机设备渲染图:

车间模型全景360旋转:

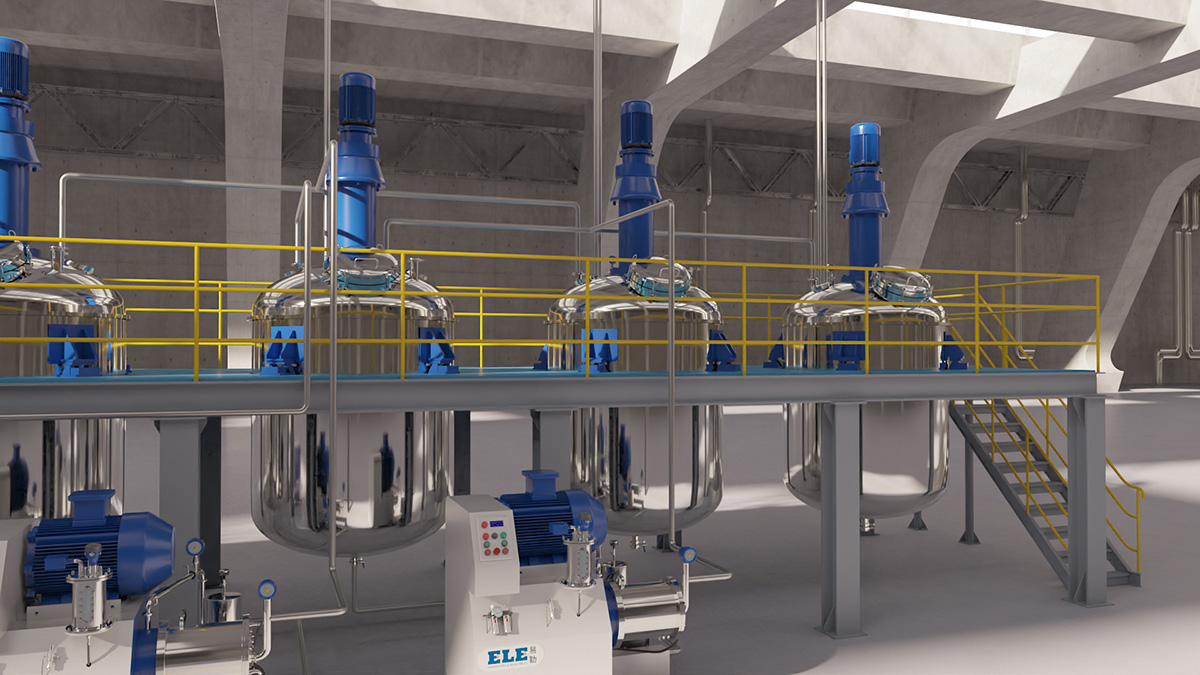

车间设备3D渲染图:

产品广告渲染图:

车间3D渲染图片:

车间机械臂生产线3D渲染:

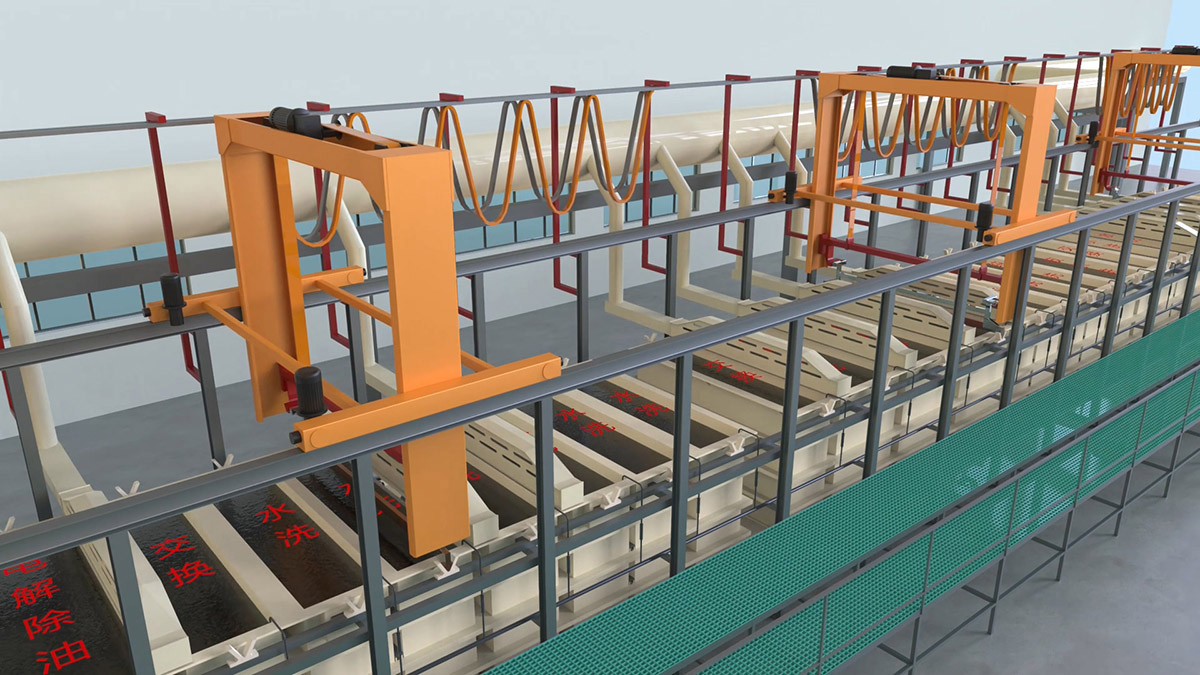

酸洗车间三维效果图:

生产车间布置效果图:

回转窑生产工艺3D效果图:

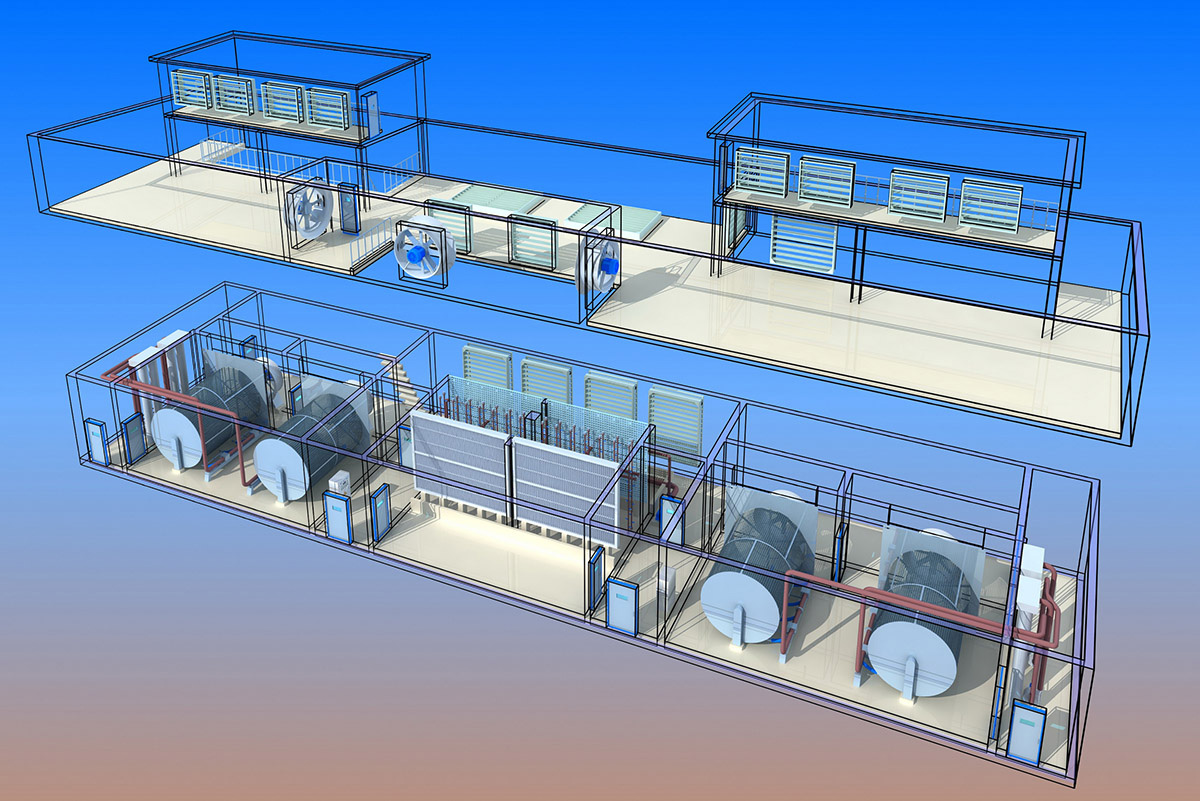

工业设备布置效果图展示:

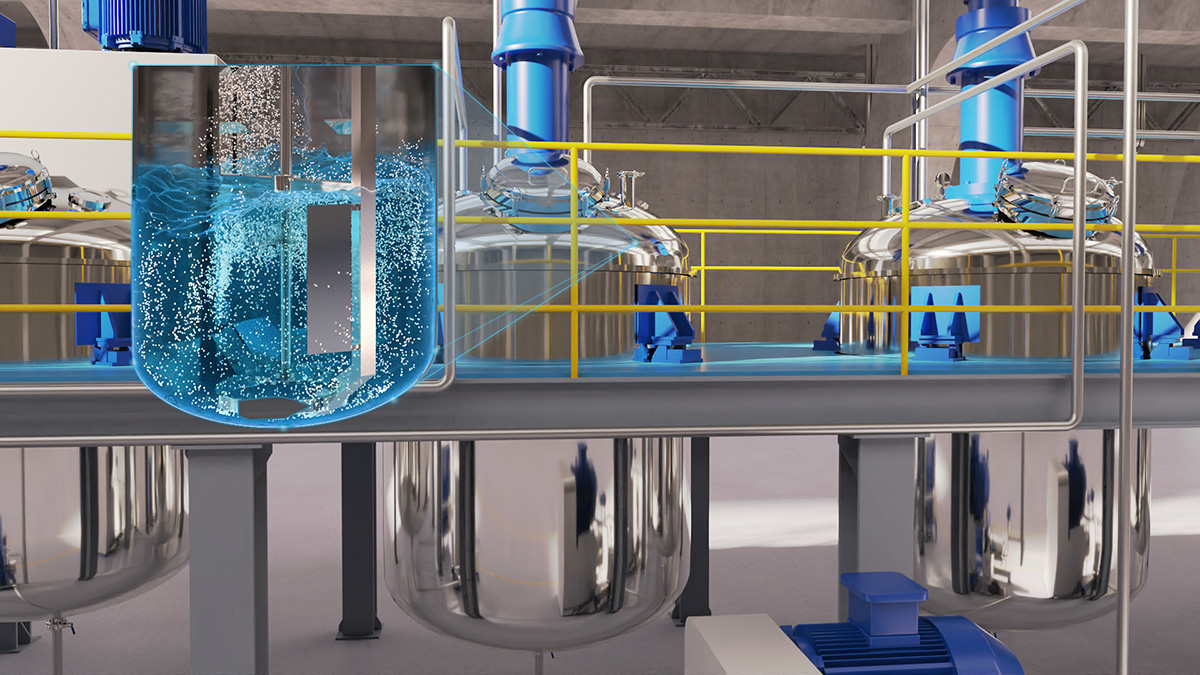

化肥厂生产车间3D渲染图:

钢平台车间三维渲染动画截图:

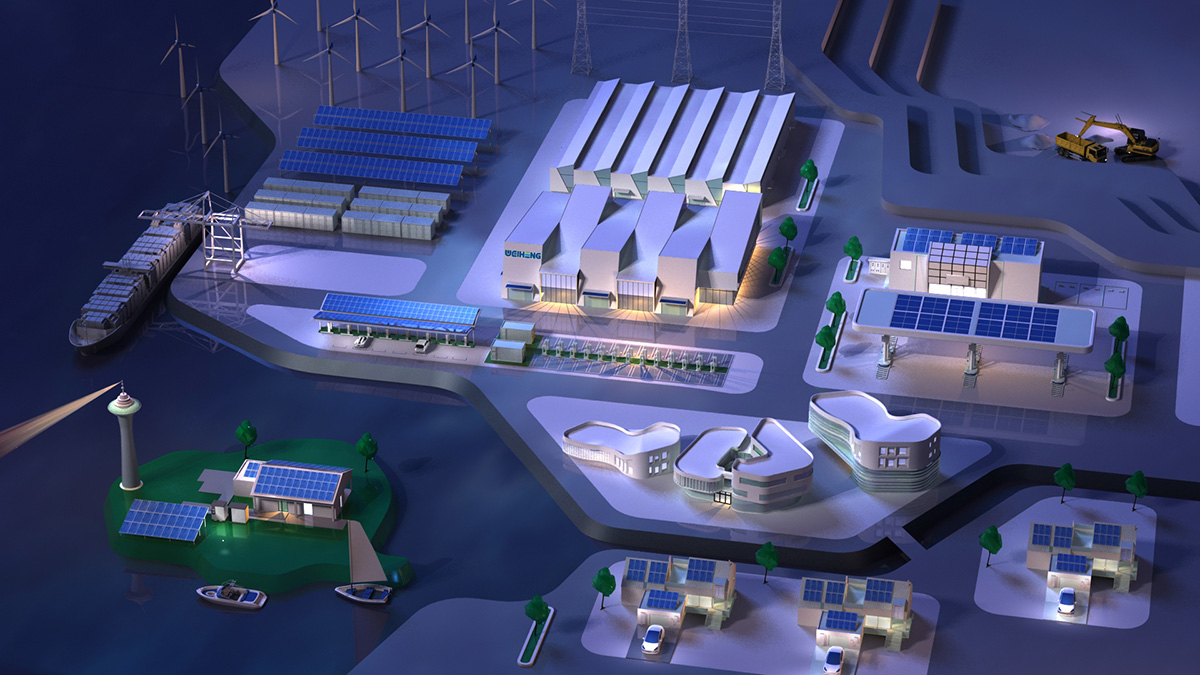

企业环保工艺效果图渲染:

实验室车间方案效果图:

化肥车间人视效果图:

******** 点击 返回主页_看更多案例 ********

车间3D渲染图是一种将车间以逼真的方式呈现在平面上的技术手段。通过虚拟现实技术,车间3D渲染图能够展示车间的各个细节和构造,增强对车间的理解和认识。具体来说,车间3D渲染图具有以下几个方面的应用和优势:

1.设计阶段的应用:设计师可以通过3D渲染图观察和调整车间的各个部分,包括机器设备的布局、管道的走向、空间布局等。这种方式不仅提高了设计师们的工作效率,而且减少了设计中的错误和遗漏。

2.施工指导:工程师们可以利用3D渲染图清楚地看到每个细节的位置和如何安装,从而减少人为误差,更好地组织和安排施工流程,确保施工的顺利进行。

3.销售和宣传:销售人员可以利用3D渲染图展示车间的各个优势和特点,吸引潜在买家的注意力。同时,渲染图可以让潜在买家直观地了解车间的空间利用率和生产流程,提高销售效果。

4.安全评估和风险预防:在3D渲染图中,可以模拟各种可能的危险场景,如火灾、泄漏等。这样,安全评估人员可以在设计阶段就发现潜在的安全隐患,并找到相应的解决方案,减少安全事故的发生。

3D渲染是指将3D模型转化为具有真实感图像的过程。这涉及将3D场景中的对象转换为二维图像,通过计算机算法模拟光线在场景中的传播和与物体的交互,生成逼真的图像。具体过程包括:

建模:构建车间的三维模型。

材质和环境灯光布置:调整材质和灯光效果。

渲染:通过计算机算法模拟光线与物体的交互,生成逼真的图像。

后期处理:进行氛围和细节的调整,最终生成高质量的渲染图2。

车间3D渲染图是一种将车间以逼真的方式呈现在平面上的技术手段。通过虚拟现实技术,车间3D渲染图能够展示车间的各个细节和构造,增强对车间的理解和认识。具体来说,车间3D渲染图具有以下几个方面的应用和优势:

设计阶段的应用:设计师可以通过3D渲染图观察和调整车间的各个部分,包括机器设备的布局、管道的走向、空间布局等。这种方式不仅提高了设计师们的工作效率,而且减少了设计中的错误和遗漏。

施工指导:工程师们可以利用3D渲染图清楚地看到每个细节的位置和如何安装,从而减少人为误差,更好地组织和安排施工流程,确保施工的顺利进行。

销售和宣传:销售人员可以利用3D渲染图展示车间的各个优势和特点,吸引潜在买家的注意力。同时,渲染图可以让潜在买家直观地了解车间的空间利用率和生产流程,提高销售效果。

安全评估和风险预防:在3D渲染图中,可以模拟各种可能的危险场景,如火灾、泄漏等。这样,安全评估人员可以在设计阶段就发现潜在的安全隐患,并找到相应的解决方案,减少安全事故的发生。

3D渲染的基本原理和技术细节

3D渲染是指将3D模型转化为具有真实感图像的过程。这涉及将3D场景中的对象转换为二维图像,通过计算机算法模拟光线在场景中的传播和与物体的交互,生成逼真的图像。具体过程包括:

建模:构建车间的三维模型。

材质和环境灯光布置:调整材质和灯光效果。

渲染:通过计算机算法模拟光线与物体的交互,生成逼真的图像。

后期处理:进行氛围和细节的调整,最终生成高质量的渲染图。

研磨机设备的渲染图可用于展示研磨机的外观、结构和功能。研磨机设备的渲染图类别有

单轴研磨机:适用于高精度的研磨需求,常用于精密零件的加工。单轴研磨机的渲染图展示了其主体机构和主要结构,包括三爪定心卡盘、接水槽等部件。

振动研磨机:用于工件表面的粗抛光和精抛光处理,适用于多种材料的表面处理。振动研磨机的渲染图展示了其工作容器和内部结构,用于工件表面研磨抛光处理。

立式研磨机:广泛应用于涂料、染料、油墨等行业,具有高效、易操作的特点。立式研磨机的渲染图展示了其在不同行业中的应用,如涂料、染料、油墨等行业的高效研磨设备。

这些渲染图不仅展示了研磨机的外观和结构,还帮助用户更好地理解其功能和适用场景。

机械臂生产线3D渲染是指使用计算机图形技术将机械臂生产线的设计转化为三维图像的过程。这一过程包括创建生产线中各个组件的3D模型,并通过渲染技术将其呈现为逼真的图像或动画。3D渲染在机械臂生产线中的应用分为:

设计阶段:在机械臂生产线的初步设计阶段,3D渲染技术可以帮助设计师直观地展示生产线的设计方案,便于与客户和团队沟通,减少设计错误和修改次数。

生产准备:在生产线实际建设之前,通过3D渲染技术可以模拟生产线的运行情况,发现潜在问题并进行优化,减少实际建设中的困难和成本。

维护和培训:3D渲染还可以用于生产线的维护和操作培训,通过模拟操作过程,帮助操作人员更好地理解生产线的工作原理和操作方法。

3D渲染的基本原理和技术是将三维模型转换为二维图像的过程。主要技术包括:

光线追踪:通过模拟光线在场景中的传播路径来计算物体的颜色和亮度,生成真实的阴影和反射效果。

辐射度算法:基于能量守恒原理计算物体表面的辐射能量,生成真实的全局光照效果。

全局光照:综合考虑场景中所有光线传播和物体表面反射、折射等现象,生成逼真的光照效果。

3D渲染软件和工具包括:

3ds Max:由Autodesk公司开发,具有强大的3D建模、渲染和效果呈现功能。

Maya:由Autodesk提供,适用于复杂的动画和视觉效果制。

Blender:开源软件,功能强大且免费,适合初学者和专业人士。

Cinema 4D:适用于快速原型设计和高效的渲染性能。

酸洗车间的3D渲染效果图是通过三维建模技术创建的视觉表现,用于展示酸洗车间的布局、设备和工艺流程。3D渲染效果图的作用和价值是可以帮助设计师直观地展示车间的布局和设备配置,确保设计的可行性和合理性。通过3D渲染,可以提前发现潜在的问题并进行调整,从而减少实际建设中的错误和成本。此外,3D渲染效果图还可以用于项目招标、客户展示和工厂参观,提升项目的专业性和可信度。

酸洗车间的设计和工艺流程的设计需要考虑多个因素,包括酸洗槽的布局、喷嘴的角度和流量、带钢的进出口设计等。通过流场模拟和仿真分析,可以优化酸洗槽内的流体动力学,提高酸洗效率和质量。具体工艺流程包括带钢进入酸洗槽、酸液与带钢表面反应、带钢出槽等步骤。通过调整喷嘴角度和带钢速度,可以改善酸洗效果,确保带钢表面处理达到预期标准。

工业设备布置效果图是指通过图形设计软件或CAD软件创建的,用于展示工业设备在特定空间内的布置情况的可视化图纸。这些图纸通常包括设备的平面布置图、立面布置图以及相关的细节设计,旨在帮助设计者、工程师和决策者直观地理解设备的安装位置、相互关系以及整体布局的合理性。

工业设备布置效果图的作用:

直观展示:通过效果图,可以直观地展示设备的布置情况,帮助相关人员更好地理解设计意图。

优化设计:在设计阶段,效果图可以帮助发现设计中存在的问题,如空间利用不合理、设备间干扰等,从而进行优化。

沟通工具:效果图是设计师与客户、工程师之间沟通的有效工具,能够清晰地传达设计意图和方案。

施工指导:在施工过程中,效果图可以作为现场施工的参考,确保设备的正确安装和布局。

工业设备布置效果图的制作流程

资料准备:收集设备的相关信息,包括尺寸、重量、安装要求等。

设计软件使用:使用CAD软件或专业设计软件进行绘制,创建设备的三维模型和布置图。

细节调整:根据实际需求调整设备的布置,确保满足工艺和生产要求。

效果图生成:完成设计后,生成效果图,包括平面图、立面图等。

审核与修改:效果图完成后,进行审核,根据反馈进行必要的修改。

工业设备布置效果图的常见类型和应用场景

平面布置图:展示设备在平面上的位置和相互关系。

立面布置图:展示设备在垂直方向上的布置情况。

三维模型:通过三维建模软件创建设备的三维模型,更直观地展示设备的空间关系。

细节设计图:展示设备的具体细节和安装要求。

这些效果图在化工、制药、机械制造等多个工业领域都有广泛应用,帮助设计和施工单位更好地完成项目。

钢结构平台三维渲染效果图是通过计算机图形技术生成的,用于展示钢结构平台的外观和结构细节的图像。

钢结构平台三维渲染效果图的特点和用途:

外观展示:渲染效果图能够真实地展示钢结构平台的外观,包括颜色、材质和光影效果,帮助用户直观地了解平台的视觉效果。

结构细节:通过渲染效果图,可以清晰地展示钢结构平台的各个部件和连接方式,便于设计和施工过程中的细节把控。

优化设计:在正式建造前,通过渲染效果图可以进行多次修改和优化,减少实际建造中的错误和成本。

钢结构平台三维渲染效果图的应用场景:

建筑设计:在建筑设计阶段,渲染效果图可以帮助设计师和客户更好地沟通设计意图,确保设计方案符合预期。

施工指导:在施工前,通过渲染效果图可以让施工人员更好地理解设计意图,确保施工过程的顺利进行。

产品展示:对于需要展示钢结构平台产品的企业,渲染效果图可以作为产品宣传材料,提升产品的市场竞争力。

钢结构平台三维渲染效果图的制作流程和技术要求:

建模:首先根据设计图纸在三维建模软件中创建钢结构平台的模型。

材质和灯光设置:为模型赋予真实的材质和灯光效果,模拟真实环境中的视觉体验。

渲染:使用专业的渲染软件进行渲染,生成高质量的图像或动画。

后期处理:对渲染结果进行后期处理,如色彩调整、光影优化等,以达到最佳视觉效果。

我们是专业3d渲染制作,产品渲染图制作,工业模型渲染,模型渲染,设备渲染图制作公司,擅长企业医疗器械、助行器、电力设备、产品、机械设备、化工工艺、安装、组装、工业机电设备、水利设备、石化设备、电力工程建设、电梯、施工、机械、钢构、投标、建筑规划设计、工业园区厂房、环保、光伏发电等领域,提供专业的3d渲染设计服务,并拥有大量3D动画制作+3d产品模型外观渲染图制作经验。

企业环保工艺三维渲染效果图是通过计算机三维仿真软件技术模拟真实环境的高仿真虚拟图片,主要用于展示环保工艺流程的细节和效果。这种效果图能够直观地呈现工艺流程中的各个环节和设备布局,帮助设计者发现潜在的设计冲突和不合理之处,并在设计阶段进行优化调整,从而减少后期修改和返工的成本。

环保工艺三维渲染效果图的作用和优势:

提升设计效率与精度:通过精确的三维建模,三维工艺流程图能够真实模拟工艺流程中的各个环节和设备布局,帮助设计者快速发现潜在的设计冲突和不合理之处,提升设计的精确性和效率。

增强沟通与协作:其直观性强的特点使得非专业人士也能轻松理解复杂的工艺流程和设备布局,促进跨部门之间的有效沟通与协作,共同推动项目的顺利进行。

优化生产流程与资源配置:通过模拟分析,企业可以更加精确地掌握生产过程中的物料流动、能源消耗、人员配置等情况,优化生产流程,减少资源浪费,提高生产效率。

支持培训与仿真演练:在员工培训和仿真演练方面也发挥着重要作用,通过模拟真实的生产环境和操作流程,提高操作技能和应急处理能力。

环保工艺三维渲染效果图的应用场景:

建筑和室内设计:在建筑和室内设计中,渲染效果图有助于客户理解设计方案,确认细节,节省时间和成本。

影视制作:在影视制作中,渲染效果图用于创建复杂特效,提升影片观赏性。

工业设计和生产:在工业设计和生产中,三维工艺流程图用于展示复杂的工艺流程和设备布局,促进跨部门沟通与协作,优化生产流程。

后期处理:使用图形处理软件(如Photoshop)对渲染结果进行进一步加工和修饰,以达到最佳视觉效果。

我们是专业的3d渲染制作公司-工业产品设备3d模型,产品外观渲染图制作,专业制作三维渲染图的动画公司,为企业、政府机构、科教院校、设计院、工程建设安装施工、房地产、新能源环保行业、电器数码产品工业、智能家居、装饰公司、汽车智能系统、石油化工业、医疗器械设备、机械产品制造业、生产线企业、铁路采掘业、纺织业、船舶航空领域,提供一站式方案设计,打造企事业形象、提高品牌竞争力。

Workshop 3D rendering is a technical means of presenting workshops in a realistic way on a flat surface. Through virtual reality technology, 3D renderings of the workshop can showcase various details and structures, enhancing understanding and recognition of the workshop. Specifically, workshop 3D rendering has the following applications and advantages:

1. Application in the design phase: Designers can observe and adjust various parts of the workshop through 3D rendering, including the layout of machinery and equipment, the direction of pipelines, spatial layout, etc. This approach not only improves the work efficiency of designers, but also reduces errors and omissions in the design.

2. Construction guidance: Engineers can use 3D renderings to clearly see the location and installation of each detail, thereby reducing human errors, better organizing and arranging the construction process, and ensuring the smooth progress of construction.

3. Sales and Promotion: Salespeople can use 3D rendering to showcase the various advantages and features of the workshop, attracting the attention of potential buyers. Meanwhile, rendering images can provide potential buyers with a visual understanding of the space utilization and production process in the workshop, thereby improving sales effectiveness.

4. Safety assessment and risk prevention: In 3D rendering, various possible hazardous scenarios can be simulated, such as fires, leaks, etc. In this way, safety assessors can identify potential safety hazards during the design phase and find corresponding solutions to reduce the occurrence of safety accidents.

3D rendering refers to the process of transforming a 3D model into a realistic image. This involves converting objects in a 3D scene into 2D images, simulating the propagation of light in the scene and the interaction with objects through computer algorithms, and generating realistic images. The specific process includes:

Modeling: Build a 3D model of the workshop.

Material and ambient lighting layout: Adjust material and lighting effects.

Rendering: Simulating the interaction between light and objects through computer algorithms to generate realistic images.

Post processing: Adjust the atmosphere and details to generate high-quality rendering image 2.

Workshop 3D rendering is a technical means of presenting workshops in a realistic way on a flat surface. Through virtual reality technology, 3D renderings of the workshop can showcase various details and structures, enhancing understanding and recognition of the workshop. Specifically, workshop 3D rendering has the following applications and advantages:

Application in the design phase: Designers can observe and adjust various parts of the workshop, including the layout of machinery and equipment, the direction of pipelines, spatial layout, etc., through 3D rendering. This approach not only improves the work efficiency of designers, but also reduces errors and omissions in the design.

Construction guidance: Engineers can use 3D renderings to clearly see the location and installation of each detail, thereby reducing human errors, better organizing and arranging the construction process, and ensuring smooth construction.

Sales and Promotion: Salespeople can use 3D rendering to showcase the various advantages and features of the workshop, attracting the attention of potential buyers. Meanwhile, rendering images can provide potential buyers with a visual understanding of the space utilization and production process in the workshop, thereby improving sales effectiveness.

Safety assessment and risk prevention: In 3D rendering, various possible hazardous scenarios can be simulated, such as fires, leaks, etc. In this way, safety assessors can identify potential safety hazards during the design phase and find corresponding solutions to reduce the occurrence of safety accidents.

Basic principles and technical details of 3D rendering

3D rendering refers to the process of transforming a 3D model into a realistic image. This involves converting objects in a 3D scene into 2D images, simulating the propagation of light in the scene and the interaction with objects through computer algorithms, and generating realistic images. The specific process includes:

Modeling: Build a 3D model of the workshop.

Material and ambient lighting layout: Adjust material and lighting effects.

Rendering: Simulating the interaction between light and objects through computer algorithms to generate realistic images.

Post processing: Adjust the atmosphere and details to generate high-quality renderings.

The rendering diagram of the grinding machine equipment can be used to display the appearance, structure, and function of the grinding machine. The types of rendering images for grinding machine equipment include

Single axis grinding machine: suitable for high-precision grinding needs, commonly used for the processing of precision parts. The rendering of the single axis grinder shows its main mechanism and main structure, including three jaw centering chuck, water receiving groove and other components.

Vibration grinding machine: used for rough polishing and fine polishing of workpiece surfaces, suitable for surface treatment of various materials. The rendering of the vibration grinder shows its working container and internal structure, used for surface grinding and polishing of workpieces.

Vertical grinder: widely used in industries such as coatings, dyes, inks, etc., it has the characteristics of high efficiency and easy operation. The rendering of the vertical grinder shows its application in different industries, such as efficient grinding equipment for coatings, dyes, inks, and other industries.

These renderings not only showcase the appearance and structure of the grinder, but also help users better understand its functions and applicable scenarios.

The 3D rendering of a robotic arm production line refers to the process of using computer graphics technology to transform the design of the robotic arm production line into a three-dimensional image. This process involves creating 3D models of various components in the production line and presenting them as realistic images or animations through rendering techniques. The application of 3D rendering in robotic arm production lines is divided into:

Design stage: In the preliminary design stage of the robotic arm production line, 3D rendering technology can help designers visually display the design scheme of the production line, facilitate communication with customers and teams, and reduce design errors and modifications.

Production preparation: Before the actual construction of the production line, 3D rendering technology can simulate the operation of the production line, identify potential problems and optimize them, reducing difficulties and costs in actual construction.

Maintenance and Training: 3D rendering can also be used for maintenance and operation training of production lines. By simulating the operation process, it helps operators better understand the working principles and operation methods of the production line.

The basic principle and technology of 3D rendering is the process of converting a 3D model into a 2D image. The main technologies include:

Ray tracing: calculates the color and brightness of objects by simulating the propagation path of light in the scene, generating realistic shadows and reflection effects.

Radiance algorithm: Based on the principle of energy conservation, the radiation energy on the surface of an object is calculated to generate the true global illumination effect.

Global Lighting: Taking into account the propagation of all light rays in the scene and phenomena such as surface reflection and refraction of objects, a realistic lighting effect is generated.

3D rendering software and tools include:

3ds Max: Developed by Autodesk, it has powerful 3D modeling, rendering, and rendering capabilities.

Maya: provided by Autodesk, suitable for complex animation and visual effects.

Blender: an open-source software that is powerful and free, suitable for both beginners and professionals.

Cinema 4D: Suitable for rapid prototyping and efficient rendering performance.

The 3D rendering rendering rendering of the pickling workshop is a visual representation created through 3D modeling technology, used to showcase the layout, equipment, and process flow of the pickling workshop. The role and value of 3D rendering renderings is to help designers visually display the layout and equipment configuration of the workshop, ensuring the feasibility and rationality of the design. Through 3D rendering, potential issues can be identified in advance and adjusted, thereby reducing errors and costs in actual construction. In addition, 3D rendering renderings can also be used for project bidding, customer presentations, and factory visits to enhance the professionalism and credibility of the project.

The design of the pickling workshop and the design of the process flow need to consider multiple factors, including the layout of the pickling tank, the angle and flow rate of the nozzle, and the design of the inlet and outlet of the strip steel. Through flow field simulation and simulation analysis, the fluid dynamics inside the pickling tank can be optimized to improve pickling efficiency and quality. The specific process flow includes steps such as the strip entering the pickling tank, the reaction between the acid solution and the surface of the strip, and the strip exiting the tank. By adjusting the nozzle angle and strip speed, the pickling effect can be improved to ensure that the surface treatment of the strip meets the expected standards.

Industrial equipment layout rendering refers to a visual drawing created through graphic design software or CAD software to display the layout of industrial equipment in a specific space. These drawings typically include equipment floor plans, elevation plans, and related detailed designs, aimed at helping designers, engineers, and decision-makers intuitively understand the installation location, interrelationships, and overall layout rationality of the equipment.

The function of industrial equipment layout rendering:

Intuitive display: Through renderings, the layout of the equipment can be visually displayed, helping relevant personnel better understand the design intent.

Optimization design: During the design phase, renderings can help identify problems in the design, such as unreasonable space utilization and interference between devices, and optimize accordingly.

Communication tool: Rendering is an effective tool for communication between designers, clients, and engineers, which can clearly convey design intentions and solutions.

Construction guidance: During the construction process, renderings can serve as a reference for on-site construction, ensuring the correct installation and layout of equipment.

The production process of industrial equipment layout renderings

Data preparation: Collect relevant information about the equipment, including dimensions, weight, installation requirements, etc.

Design software usage: Use CAD software or professional design software to draw, create 3D models and layout plans of equipment.

Detail adjustment: Adjust the layout of equipment according to actual needs to ensure compliance with process and production requirements.

Rendering generation: After completing the design, generate renderings, including floor plans, elevations, etc.

Review and modification: After the rendering is completed, review it and make necessary modifications based on feedback.

Common types and application scenarios of industrial equipment layout renderings

Layout plan: Display the position and mutual relationship of equipment on the plane.

Facade layout: Display the arrangement of equipment in the vertical direction.

3D model: Create a 3D model of the equipment using 3D modeling software to more intuitively display the spatial relationships of the equipment.

Detail design diagram: Display the specific details and installation requirements of the equipment.

These renderings are widely used in various industrial fields such as chemical, pharmaceutical, and mechanical manufacturing, helping design and construction units better complete projects.

The 3D rendering rendering effect of the steel structure platform is generated through computer graphics technology, which is used to display the appearance and structural details of the steel structure platform.

The characteristics and uses of 3D rendering renderings for steel structure platforms:

Appearance display: Rendering renderings can realistically display the appearance of the steel structure platform, including color, material, and lighting effects, helping users intuitively understand the visual effects of the platform.

Structural details: By rendering renderings, the various components and connection methods of the steel structure platform can be clearly displayed, making it easier to control the details during the design and construction process.

Optimization design: Before formal construction, multiple modifications and optimizations can be made through rendering renderings to reduce errors and costs in actual construction.

Application scenarios of 3D rendering effects on steel structure platforms:

Architectural design: During the architectural design phase, rendering renderings can help designers and clients better communicate design intentions and ensure that the design scheme meets expectations.

Construction guidance: Before construction, rendering renderings can help construction personnel better understand the design intent and ensure the smooth progress of the construction process.

Product Display: For enterprises that need to showcase their steel structure platform products, rendering renderings can serve as promotional materials to enhance the product's market competitiveness.

The production process and technical requirements for 3D rendering renderings of steel structure platforms:

Modeling: First, create a model of the steel structure platform in 3D modeling software based on the design drawings.

Material and lighting settings: Assign realistic material and lighting effects to the model, simulating the visual experience in a real environment.

Rendering: Use professional rendering software to render and generate high-quality images or animations.

Post processing: Post processing the rendering results, such as color adjustment, light and shadow optimization, to achieve the best visual effect.

We are a professional company specializing in 3D rendering production, product rendering, industrial model rendering, model rendering, and equipment rendering. We specialize in enterprise medical equipment, walkers, power equipment, products, mechanical equipment, chemical processes, installation, assembly, industrial electromechanical equipment, water conservancy equipment, petrochemical equipment, power engineering construction, elevators, construction, machinery, steel structure, bidding, architectural planning and design, industrial park buildings, environmental protection, photovoltaic power generation, and other fields. We provide professional 3D rendering design services and have extensive experience in 3D animation production and 3D product model appearance rendering.

The 3D rendering effect diagram of enterprise environmental protection process is a highly simulated virtual image that simulates the real environment through computer 3D simulation software technology, mainly used to display the details and effects of environmental protection process flow. This type of rendering can visually present various stages and equipment layouts in the process flow, helping designers identify potential design conflicts and inconsistencies, and optimize and adjust them during the design phase, thereby reducing the cost of later modifications and rework.

The role and advantages of environmentally friendly 3D rendering renderings:

Improving design efficiency and accuracy: Through precise 3D modeling, 3D process flow diagrams can simulate various links and equipment layouts in the process flow, helping designers quickly identify potential design conflicts and irrationalities, and improving the accuracy and efficiency of design.

Enhance communication and collaboration: Its intuitive nature allows non professionals to easily understand complex process flows and equipment layouts, promoting effective communication and collaboration across departments and jointly driving the smooth progress of projects.

Optimizing production processes and resource allocation: Through simulation analysis, enterprises can more accurately grasp the material flow, energy consumption, personnel allocation, and other situations in the production process, optimize the production process, reduce resource waste, and improve production efficiency.

Supporting training and simulation exercises: It also plays an important role in employee training and simulation exercises, improving operational skills and emergency response capabilities by simulating real production environments and operational processes.

Application scenarios of 3D rendering effects of environmental protection technology:

Architecture and Interior Design: In architecture and interior design, rendering renderings help clients understand design proposals, confirm details, and save time and costs.

Film and television production: In film and television production, rendering effects are used to create complex special effects and enhance the viewing experience of the film.

Industrial design and production: In industrial design and production, 3D process flow diagrams are used to display complex process flows and equipment layouts, promote cross departmental communication and collaboration, and optimize production processes.

Laboratory 3D rendering renderings can help designers, architects, and engineers better showcase laboratory design schemes and visual effects by converting 3D models into realistic 2D images or animations. This technology is widely used in fields such as architecture, interior design, product design, etc. It can simulate real lighting effects and material textures, thereby generating realistic images.

The role and importance of laboratory 3D rendering renderings:

Visual Display: 3D rendering renderings can provide highly realistic visual displays, helping designers and clients better understand design solutions and reduce communication barriers.

Optimization Design: Tong

QQ咨询

QQ咨询

189 5158 0154

189 5158 0154

在线留言

在线留言